Jet skiing is a fun activity that many water sports enthusiasts enjoy and can introduce the opportunity to test out different models of jet skis on the market. Jet skis can come in a range of different shapes, sizes, and price points, with unique features to choose from. This is where some users could benefit from modifying and personalizing their jet skis according to their preferences while also enjoying the build process along the way. In this article, we will cover how Brian Zysset was able to integrate an electric reverse for his jet ski using our linear actuator!

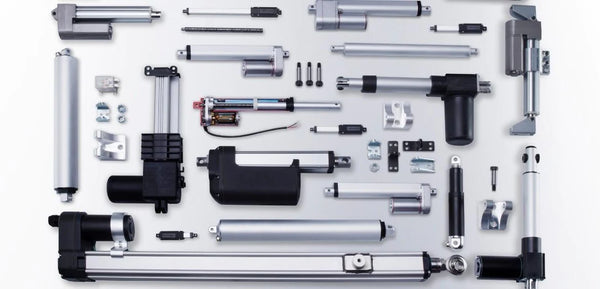

Introduction

Brian purchased his 1997.5 Seadoo GSX-L ("Grey Ghost") about a year ago to refurbish it and work on making it more reliable. This is also the platform he used for his electric reverse project. The Grey Ghost came from the factory without reverse; however, Brian was thinking about innovation to do something new and cool with the setup when he bought the jet ski and saw that it had the potential to work. Brian’s first attempt was a mechanized reverse like the traditional style seen on the GTX, but he then realized that the setup probably wouldn't hold up long term. He then went back to brainstorming other solutions and decided to go with an electric reverse system.

Finding a Bucket and Reverse Cable

In order to have a reverse function, the jet ski will require a reverse bucket similar to the 2000 RX Reverse Gate, nozzle, and spring. This bucket drops into position so that the nozzle can spray water downwards and head in a direction toward the front of the jet ski. Connected to the bucket is the 2000 LRV Reverse Cable which was chosen because of its length towards the front.

Choosing an Actuator

After doing some research, Brian found that he would need an electric linear actuator for motion to drive the reverse cable. His decision was to use our PA-06-2-180 Waterproof Actuator as it had all the specifications he was looking for. Initially, Brian was worried that the motor would get hot, especially when there was thrust out of the back nozzle while the actuator would try to wind the bucket back in. However, Brian kept monitoring the actuator in his tests and found that it would not overheat. These tests under load demonstrate that its performance was excellent as it did everything Brian wanted.

In terms of durability, Brian’s impression of the PA-06 was that it's put together well and built like a tank. With a hefty weight, he feels like if the actuator gets knocked around, it's really going to hold up (and so far, it has!). The ingress protection rating of IP67M also ensures waterproof protection while using the jet ski. When Brian compared us with other companies, he found our PA-06 to be priced very reasonably, especially after talking and communicating with our technical support team who was helpful and responsive whenever he had any questions.

The only reservation Brian had with the actuator is that it runs at a bit of a slower speed. However, he is aware that the actuator’s gear ratio has a slower speed to allow for a higher weight capacity rating for more load. While Brian could have purchased a light-duty linear actuator with a slightly faster speed, he thinks this would risk running into overheating issues and could break the unit because of how much force the application needed. Overall, Brian is very happy with the PA-06 actuator and would grade us 5/5 stars based on his experiences and how pleased he is with everything.

See the full product review video of our PA-06 Waterproof Linear Actuator below!:

Attaching the Actuator and Cable

The PA-06 actuator is attached by Brian to the push-pull cable from a 2000 LRV Reverse Cable. Depending on where you decide to set up your actuator to a jet ski, the required length between the actuator and push-pull cable can vary.

Mountings for the Actuator and Cable

For securing the PA-06 actuator, Brian used the rear bracket of our BRK-06 to secure the actuator’s rear mounting hole. An Anodized Aluminum L-angle (Ace Hardware) was then used to fasten the BRK-06 mounting bracket holding the PA-06 actuator. Brain also had to fabricate a smaller bracket to be mounted on the larger Anodized Aluminum L-angle for securing one end of the cable.

Wiring and Waterproofing the Electronics

For power, Brian uses the +12VDC from a solenoid which receives power from the two-cycle source battery in the back of the jet ski. The grounding wire for the rest of his added components were connected together with the other grounding wires on the jet ski for extra safety.

Since the jet ski will be exposed to lots of water, waterproofing all the electronics is crucial for ensuring proper operation and safety. For waterproofing the electronic components, Brian used extra insulation, plastic hoses, protective tubing for wiring, and waterproof 2-pin connectors.

In order to extend and retract a 12 V electric actuator, the +12 VDC and GND being applied to the two pins on the actuator’s terminals must have the ability to reverse polarities for both sides. For this reason, a double throw waterproof relay and 10 Amp diode was integrated so Brian could use his two waterproof single pole single throw type push buttons (VTS Switch Assembly) to control the PA-06 actuator’s motion. The actuator’s wiring was secured using zip ties with bases supplemented with gorilla glue before applying.

Modifying the Information Center

Since the original information center on the outside of the jet ski had two fake buttons that had nothing behind them and didn't really flex when being pressed, Brian had some modification work to do. He replaced the fake buttons with used buttons and wrote indicators for forward (F) and reverse (R) with a marker.

Controlling the Jet Ski

During operation, it takes about four seconds to put fully into reverse, about three seconds to put in neutral, and four seconds to bring the bucket back up so it is fully into forward. Controls became a little bit different for Brian as he now had to get used to taking his hand off the handlebars when deciding what he wants to do. The best part of the project is that when launching the ski, Brian does not have to shake forward and try to get loose from the bunks since he can now just hit reverse and then slide easily right off with his jet ski.

Check out the full video on how to install an electric reverse on the Seadoo GSX-L Jetski!:

IN SUMMARY

By following the build process and using the right supplies, Brian now has his very own electric reverse system for his jet ski. To see more of Brian from 2-Smoke, feel free to visit his Youtube channel!

Thank you, Brian, for sharing your project! We hope you continue to enjoy your Seadoo GSX-L with electric reverse!

If you have any queries about our electric linear actuators or wish to discuss our other products further, please do not hesitate to reach out to us! We are experts in what we do and will be happy to assist in any way we can.

sales@progressiveautomations.com | 1-800-676-6123