Automated rovers are an advanced yet exciting technology for learning about our neighboring planets. Building a Rover for Mars can be a challenging task for any team, especially in the face of global uncertainties such as the pandemic. From supply chain issues and delayed shipments to limited communication and restricted in-person team interactions, team DJS Antariksh has proven that they can create a very successful Mars Rover while enduring any challenge they face! If you were interested in the European Mars Rover Challenge or have a passion for autonomous rovers, this is the article for you! We will cover the journey of team DJS Antariksh in bringing their Mars Rover to life using electric linear actuators for the European Mars Rover Challenge!

Introducing Team DJS Antariksh

Team DJS Antariksh comprises undergraduate students from various branches of engineering and is the official Mars Rover team of Dwarkadas J. Sanghvi College of Engineering, Mumbai, India. To showcase their passion for the space and robotics industry, they work together on building their Rover while also competing in various Mars Rover Challenges.

In their debut year, the team got third place Worldwide and won the Best Science Planning Award for 2020. For the European Rover Challenge (ERC) 2021 Remote, DJS Antariksh won 1st place Worldwide along with the Best Science and Best Navigation awards. Their official Mars Rover Design - “Abhigyaan”, won third place in the International Rover Design Challenge (IRDC) 2022, and was the 1st-place winner of the European Rover Challenge 2022 (REMOTE formula).

Team DJS Antariksh aims to continue forward with momentum in preparation for the International Rover Challenge 2023. Despite being from one of the worst-hit cities by the pandemic, team DJS Antariksh continues to decipher the unimaginable and strive for excellence.

Planning and Designing for the Rover

Not long after the team's members were founded for DJS Antariksh, the team's entire state was in lockdown due to the pandemic in 2020. At this time, everyone in their faculties was encouraging the team to give it their best and if anything, to at least gain as much experience and knowledge that they can. While the team had no prior knowledge or experience working on a Mars Rover, they did as much online work as they could such as research, designing, brainstorming, and performing risk analysis for their Mars Rover. The five sub-departments of the team and their roles are listed below:

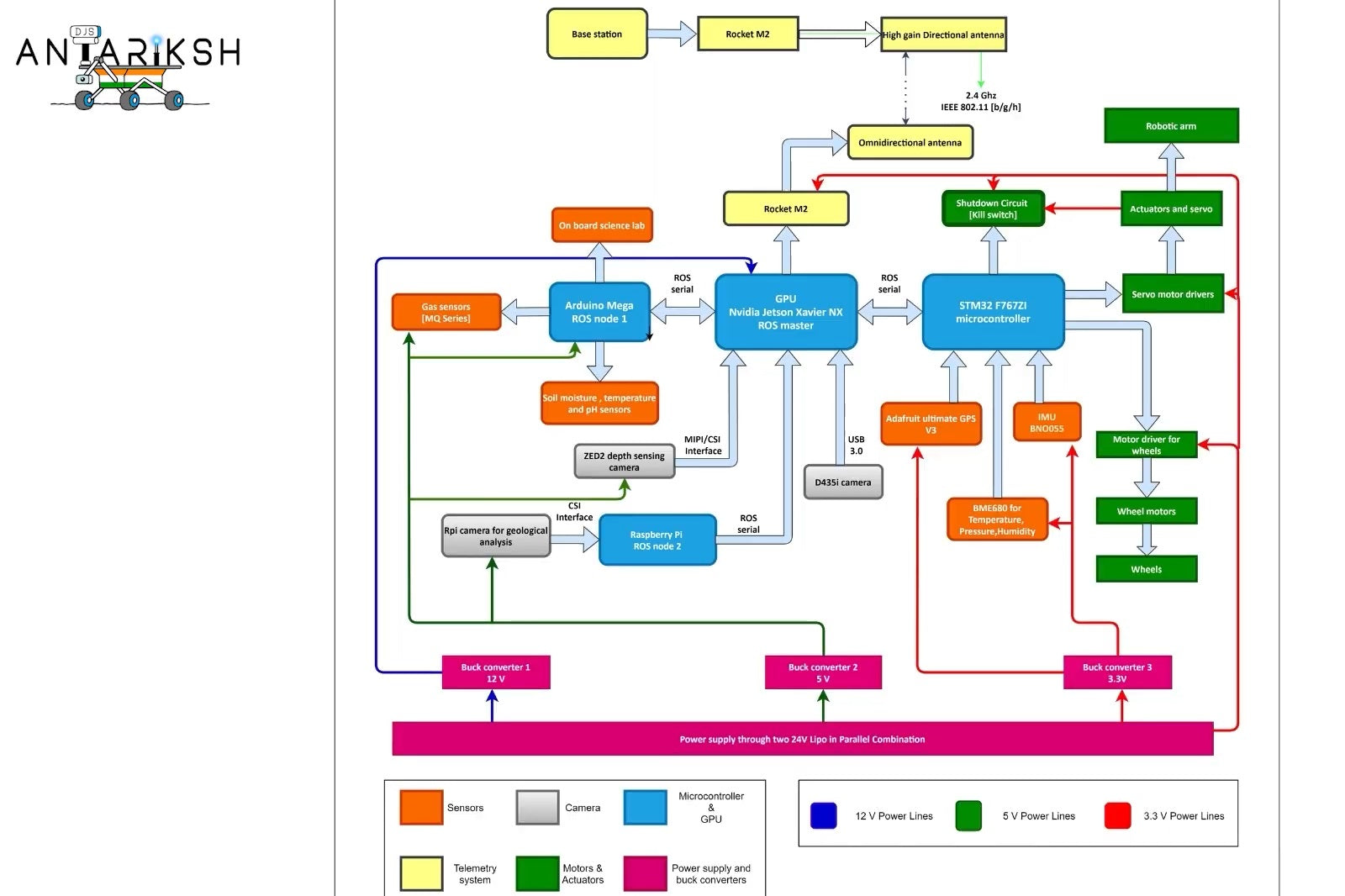

- Coding department: works on algorithms for overall rover operations and efficient object detection.

- Marketing department: responsible for complete team management and finances outreach.

- Mechanical department: handles the design, manufacturing, and testing of the rover’s structure.

- Electronics department: in charge of the development and integration of the rover’s electronic systems.

- Science department: draft hypotheses that can be tested on the landing site by studying the geological history of mars.

The team also competed in as many virtual Mars Rover Challenges as they could while their project was still in progress. Watch the full video by team DJS Antariksh below:

The ideal team interaction and essence of offline meets were not possible due to being restricted to online meets during the pandemic. Many organizations were impacted by the pandemic, which resulted in supply shortages and delays in when components were available. However, the team did their best with their online work while also collecting funds for their project and were able to acquire their first components 1.5 years down the line.

Through software such as HiRISE and JMARS, the team collected data on the geological features of Mars for developing a science mission. Everything ranging from basic subsystems to complicated subsystems in their robotic arm was designed and later built from scratch by the team. Proteus design suite software was used for the simulation of all the circuits while the team designed their industrial-level robust PCB through Altium designer.

Manufacturing the Mars Rover

After their state’s pandemic restrictions were loosening, the team was finally able to meet for offline tasks such as designing, planning, and manufacturing their Mars Rover in person. During the pandemic and their early stages of planning, certain aspects of their Mars Rover were designed with the idea of using technologies that were later found to be unavailable for the team to purchase. Due to the availability limitations and lead time for certain project components, the team had to strategically plan for the components that they will order in mid-2021.

When finalizing the newer components to be used on the Mars Rover, it was necessary to make sure these components were available in the market for the team to purchase and work on. This resulted in the manufacturing process of the Mars Rover being postponed towards the end of 2021 and the start of 2022 once the team had their plans laid out for the resources they could work with. In some cases, the team had to redesign certain subsystems and make improvisations as they go. This was so they can meet their compatibility requirements for the components they were able to acquire. The team initially started with slow-based manufacturing as this was their first time manufacturing while having very limited technologies and funding to work with.

The team ensured their project was on the right path through discussions with their faculties, seniors, and industry experts to confirm that everything purchased and machined for their parts will be suitable for what they were trying to achieve. After having multiple discussions with the experts, the team was able to bring down any delays that could be introduced into the next year. Support from partnerships and sponsors played a crucial role in the team’s project and its funding. Stainless steel fasteners from Sunrise Multi Tech Fasteners Pvt. Ltd. and workshop tools from Samsan Tools were used by the team to build their Mars Rover. The team also received their custom-printed circuit board from PCB Power Market India.

Check out the video below to learn more about working remotely for robotics projects:

Using Linear Actuators in The Mars Rover Challenge

Our PA-14P-8-150 and PA-14P-4-150 electric linear actuators are used to drive the rover’s robotic arm so that it has six degrees of freedom (6DOF). By integrating our PA-14P Feedback Linear Actuators, positional information can be read through feedback signals from the actuator’s built-in potentiometers. Having positional information enables a system to determine if the actuators have reached the required positions to minimize errors and allow for high accuracy. Besides that, these electric-motor driven actuators also happened to have a compact size and lightweight design to assist in keeping the low mass of the overall Rover for Mars.

“The rover’s manipulating device is a 6DOF robotic arm accompanied with a 2-finger gripper. The arm consists of two linear and four rotary actuators placed in positions which provide better load distribution and efficiency. The 2-finger gripper is motor based which powers and controls the kinematic gripper assembly and motion of the jaws.” - Rutwik Bhangale

For more videos by DJS Antariksh, check out their Youtube channel and latest upload below:

IN SUMMARY

Through cooperative teamwork, perseverance, and unwavering commitment, team DJS Antariksh has overcome every challenge they faced to bring a very successful Mars Rover to life. For more updates on team DJS Antariksh and their future Mars Rover challenges, feel free to follow them on Instagram, Facebook, Twitter, and LinkedIn!

Thank you to team DJS Antariksh for sharing your project and being an inspiration to everyone! We wish you the very best as you compete in the International Rover Challenge 2023!

If you have any custom projects, applications, or technical questions about our electric linear actuators, feel free to reach out to us anytime. We are experts in what we do and will be happy to assist you with your future custom projects!

sales@progressiveautomations.com | 1-800-676-6123