Dr. Decks has been one of our most valued customers for a long time and we have worked together on a number of exciting automation projects together in the past. We are partnering up again and working on an addition to his line of "Phantom" devices, this time the Phantom BBQ. Previous "Phantom" creations that we have worked on together include the Phantom Bench, Phantom Lounge Chair and Phantom Staircase projects.

All of these creations involve having outdoor furniture and appliances that are able to appear and disappear at the press of a button, giving customers more space in their backyard and saving them the hassle of setting up and putting away all those appliances manually.

The newest automated appliance we've worked together on that continues that tradition is the automated Phantom BBQ. Located on a customer's large backyard deck in Tacoma, WA, together we have been working on installing a BBQ that is able to raise and lower itself from the deck with one push of a button. When Dr. Decks came to us with the idea we knew we wanted to be a part of it and our expert engineer staff began working on a custom control system prototype for the project.

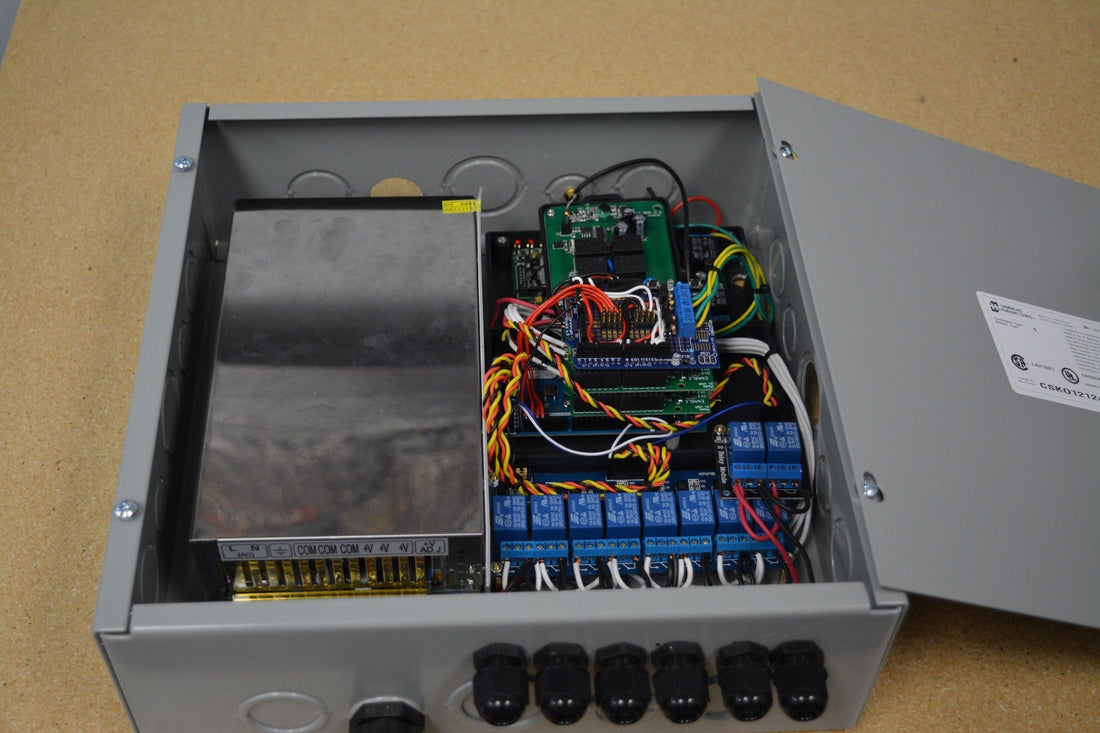

For this system, we combined a variety of our different controllers together and put it all together in a 12" x 12" x 4" enclosure. We use enclosures like this to house all the control units for customers that require a custom-built control system. The control options we used in this system were:

- 1x PS-10 power supply

- 1x PA-31 control box

- 1x PA-35 WiFI control box

- 1x LC-067 Arduino microcontroller

- 3x LC-80 MegaMoto Plus

- 1x LC-203 prototype shield

- 1x LC-202 8-channel relay

- 1x LC-201 4-channel relay

We sent our lead engineer down to the project site to help with the installation process of our prototype system. We used six actuators in conjunction with the custom control system to bring this project to life. The actuators used were four PA-04-40-100s (40" stroke, force of 100 lbs) with custom hall effect sensors added for lifting the BBQ platform and two PA-17-14-2000s (14" stroke, force of 2000 lbs) industrial actuators for opening and closing the lift door.

The PA-04 actuators were chosen mainly for their built-in IP-66 rating, making them completely impermeable to dust and able to withstand strong jets of water. This makes them ideal for outdoor use where potentially harmful weather is always a factor. The other actuators, the PA-17 were chosen because they are the strongest actuators we carry in regards to force output, capable of lifting up to 2000 pounds, perfect for the large lift door of the deck that needs to be opened and closed for the BBQ platform.

Remember that this Phantom BBQ system is still in the early stages of development and we will work on upgrading the system in the near future. Below we have a video showing off the prototype system in action and we will keep you updated once the project is completed at a later date. If this project inspired you to create your own automated appliance or if you just want to learn more about our products, don't hesitate to contact us today. We have custom actuator and control system options like the one we did for this project available for all our customers, just take a look at custom order page detailing all the customization options available.

Remember that this Phantom BBQ system is still in the early stages of development and we will work on upgrading the system in the near future. Below we have a video showing off the prototype system in action and we will keep you updated once the project is completed at a later date. If this project inspired you to create your own automated appliance or if you just want to learn more about our products, don't hesitate to contact us today. We have custom actuator and control system options like the one we did for this project available for all our customers, just take a look at custom order page detailing all the customization options available.