In agriculture, there are always new solutions being discovered and used to help boost efficiency and convenience, which ultimately helps improve productivity. This can bee seen through the examples of modifying tractors with upgrades that can enhance operation efficiency and user-friendliness. When changing a tractor from buckets to pallet forks, to grapples, the process can take up quite a lot of time when done manually. By adding modifications and integrating electric actuators onto quick-release locks, users can speed up this process for their tractors. In this article, we will cover how Chris Bolich was able to use our waterproof linear actuator to enhance his tractor’s front loader quick-release locks!

Quick-Release Locks for Front Loaders of Tractors

Tractors can cost more than cars in some cases and just like modifying cars, many tractor owners also enjoy adding their personal touches through modding or upgrading different aspects of their tractors. Another notable reason tractor customizations are gaining popularity is because of the growth in the homesteading trend.

Chris Bolich previously had to get on and off his Kubota B2601 tractor with SSQA quick attach bucket setup to lock and unlock the handles when changing front attachments. Depending on what task(s) he needs to do with the tractor, he may switch from buckets to pallet forks, to grapples, etc.

Since the SSQA mechanisms are a universal size and shape, many modifications and upgrades done on one platform should work on just about any tractor with a few small modifications. This project by Chris was relatively easy and fun while still having a huge upside when used with his tractor. He has been using our linear actuator for a few weeks now, and it makes changing from buckets to pallet forks, to grapples, etc a breeze as seen in the video below!

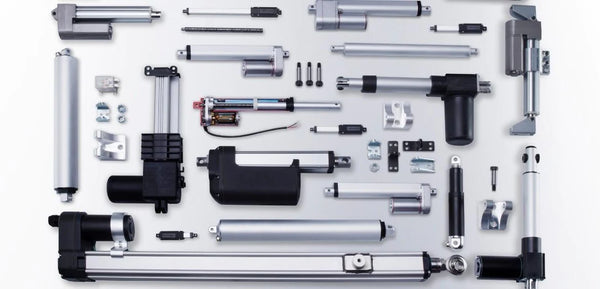

Choosing An Actuator

When selecting an actuator, Chris was looking for a compact and clean looking solution that had a good travel speed. He also required the right length actuator to meet his dimensional and stroke requirements.

In the end, Chris Bolich chose the PA-06-8-180 waterproof electric linear actuator over the more traditional shaped actuators with the motor mounted on the side. This is because the extended length of the tubular style design made for the cleanest and most professional “OEM look” while fitting perfectly for his dimensional requirements with the 8" stoke. Chris then painted the actuator an orange color for a more factory-looking installation.

Having the extra waterproof IP67M Ingress Protection rating was also a huge bonus since the PA-06 actuator will be used in an outdoor setting while exposed to water. Securing the actuator to the BRK-06 mounting brackets was done by simply mounting them onto the 1/4" plate steel arms.

“I had seen a few videos online of similar projects but they were very rudimentary, although functional. Using your PA-06 took the project to the next level!” - Chris Bolich

Wiring and Power Source

The controller used for the project was a simple LED double pole double throw KCD-W-BT rocker switch by TWTADE with latching feature and waterproof protection:

https://www.amazon.ca/TWTADE-Waterproof-Latching-Polarity-KCD4-203R-JT/dp/B08QMB8VJD?th=1

Manufacturer: TWTADE

Part Number: KCD-W-BT

Electrical power was sourced directly from the tractor’s battery with a built in 10 A fuse. The wiring was a common 14/2 vinyl jacketed wire that Chris was able to coil tightly around a rod and heat in the oven to get it to maintain the coiled shape.

This was to allow for the bucket to be dumped and curled without pinching the wire once installed onto the tractor. Since the double pole double throw rocker switch was able to handle the current draw and 2-wire actuator operation as is, no additional relays were required.

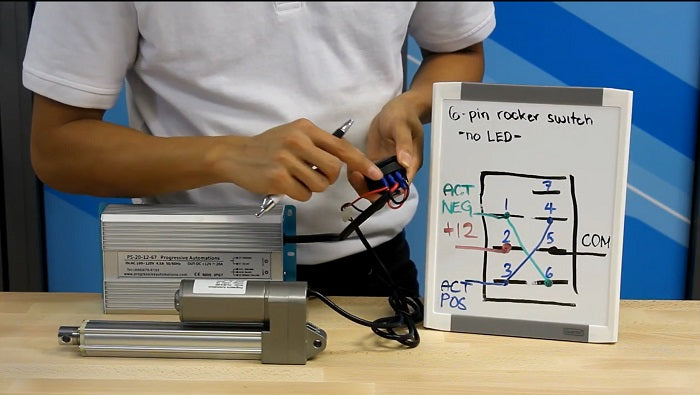

The wiring procedure in this project can be done in a similar way to our guide on how to wire our DPDT rocker switches to an actuator:

- The upper-left and lower-right terminals must be connected to the ground of the power source.

- The upper-right and lower-left terminals must be connected to the +12V terminal of the power source.

- The middle-right and middle-left terminals must be connected to the 2 inputs from the actuator.

This type of actuator switch wiring allows the operator to change the direction of electrical current flow entering the actuator in order to change travel direction. For a physical example of an actuator wiring circuit with our rocker switches, this video is a great example.

Explore our range of rocker switches and joysticks for electric actuators!

IN SUMMARY

With some creativity and using the right supplies, Chris’s tractor now has a motorized front loader quick-release locks. We hope you found this as interesting as we did, especially if you were looking for new ideas to upgrade your tractors!

Thank you, Chris Bolich, for sharing your project! We hope your tractor front loader quick-release locks continue to serve you well!

If you have any queries about our electric linear actuators or wish to discuss our other products further, please do not hesitate to reach out to us! We are experts in what we do and will be happy to assist in any way we can.

sales@progressiveautomations.com | 1-800-676-6123