Heliostats and solar panels are among the most notable devices found in the harvesting of solar power for renewable energy and reducing carbon footprint. While both technologies are used in solar energy systems, they serve different purposes and have distinct characteristics which offer different benefits in certain conditions. This article will cover the important aspects of tracking heliostats using industrial linear actuators such as their benefits, ideal use cases, and important specifications to consider.

Comparing Heliostats to Solar Panels

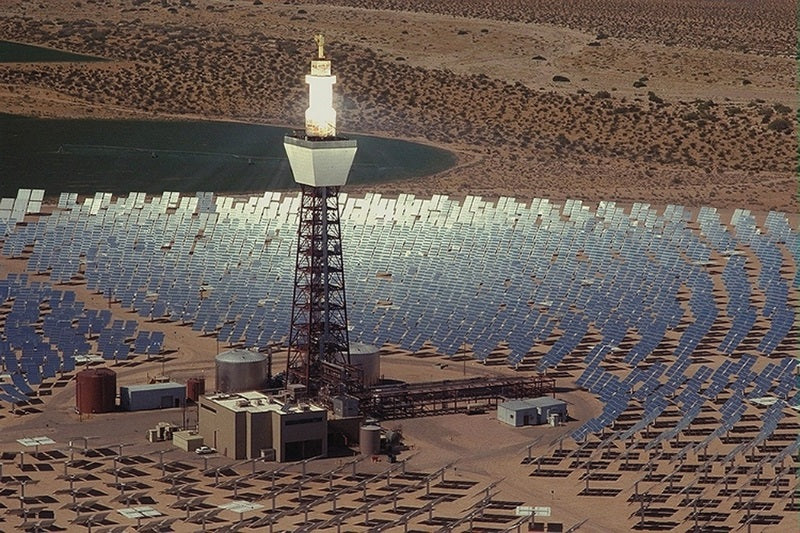

Heliostats and solar panels are both technologies used in solar energy systems, but they serve different purposes and have distinct characteristics. A heliostat is a device that uses mirrors to track the movement of the sun and reflect sunlight onto a specific target such as a central receiver. Heliostats are commonly used in concentrated solar power (CSP) systems, where concentrated sunlight is used to generate electricity or produce heat. These systems are typically large-scale and require a significant amount of space, performing at their best in areas such as large deserts. Less infrastructure is required for the utilization of heliostats compared to the integration of solar panels in an equally large area. Heliostats also achieve much higher levels of concentration than solar panels, which can lead to higher temperatures and energy production.

Solar panels directly convert sunlight into electricity through the use of semiconductor materials and will be the more commonly used option in residential, commercial, and utility-scale applications. This is because solar panels have the versatility to be installed on rooftops, ground-mounted systems, or integrated into building materials in a more compact manner. Compared to heliostats, solar panels have a lower concentration while still being able to generate electricity efficiently. The choice between heliostats and solar panels depends on the specific application, available space, cost limitations, and desired energy output.

How Heliostats are Used

By continuously adjusting the position of their mirrors, heliostats ensure that the maximum amount of sunlight is directed toward a central receiver throughout the day. This helps to maximize the efficiency of solar energy collection and utilization from the central receiver which is responsible for converting the reflected sunlight into heat energy or electricity found in a:

- solar panel

- solar thermal collector

- solar furnace

- solar cooker

- solar tower

Solar Furnaces

Often used with heliostats, a solar furnace is an enclosed heating structure that uses concentrated solar power to generate its heat. It can consist of large parabolic mirrors known as "concentrators" but may also be found together with an array of heliostat mirrors that focus sunlight onto a central point or receiver. In the right conditions, the concentrated sunlight can reach very high temperatures of over 3,500 °C. This allows the solar furnace to be used for various applications such as:

- heating fluids

- melting metals

- generating steam/steam turbines

- producing electricity

Solar Cookers

Solar cookers come in various designs, including box cookers, parabolic cookers, and panel cookers. These designs share similarities to solar furnaces but on a smaller scale by using sunlight to:

- boil water

- pasteurize drinks

- cook food

- heating up other food items

They offer a sustainable and environmentally friendly alternative to traditional cooking methods that rely on fossil fuels. As affordable and portable solutions, solar cookers are used in areas where access to electricity or gas is limited, making them particularly beneficial in developing countries.

Important Actuator Specifications in Heliostats

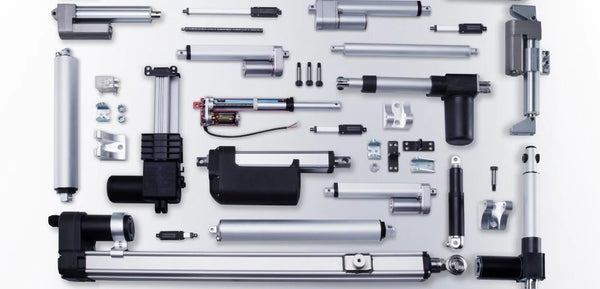

The rotation of heliostats can be from a single-axis or dual-axis system driven by actuators or slewing drives - a gearbox that can safely hold radial and axial loads, as well as transmit torque for rotation. Electric linear actuators are commonly used for solar tracking systems in solar panels and heliostats. In some cases, solar trackers may utilize a combination of actuators and slewing drives, however, the important specifications that always need to be tested and considered for these drive systems are their:

- Force rating

- Ingress Protection (IP rating)

- Feedback options

- Physical dimensions

Force Rating

Selecting the right force option for electric linear actuators is crucial for ensuring smooth operation and long life. We recommend calculating the required force of your application before purchasing an actuator. Solar applications do not have high travel speed requirements but can often benefit from having a high force rating. Aside from inherently having extra structural durability, a high force rating typically found in industrial linear actuators better guarantees there will be sufficient torque to move your heliostats into position if there were heavy gusts of wind.

Ingress Protection

Having a sufficient Ingress Protection rating ensures a longer product lifespan when exposed to water. We recommend an IP rating of at least IP66 for outdoor applications such as for heliostats. Our range of actuators have options with IP ratings available at IP66 for outdoor use all the way to IP68M dynamic/IP69K static for full submersion. Units rated for IP66 are suitable for most outdoor use as they can withstand dust and moderate liquid ingress. Having UV Ray and Salt Spray certifications such as found in our PA-100 solar tracker linear actuator also benefit the overall longevity of the unit in deserts or areas exposed to salt.

Feedback Options

Certain pre-existing systems for heliostats may require actuators with a specific type of feedback to work correctly with their controllers. Limit switches and position feedback sensors are intended to help prevent over-rotation or damage to the heliostat during operation. This is because determining an actuator’s position is useful for applications that require multiple actuators to travel at the same speed, store preset positions, and/or collect positional information for user analysis. When selecting an actuator, ensuring that it has suitable feedback is important for compatibility with your system.

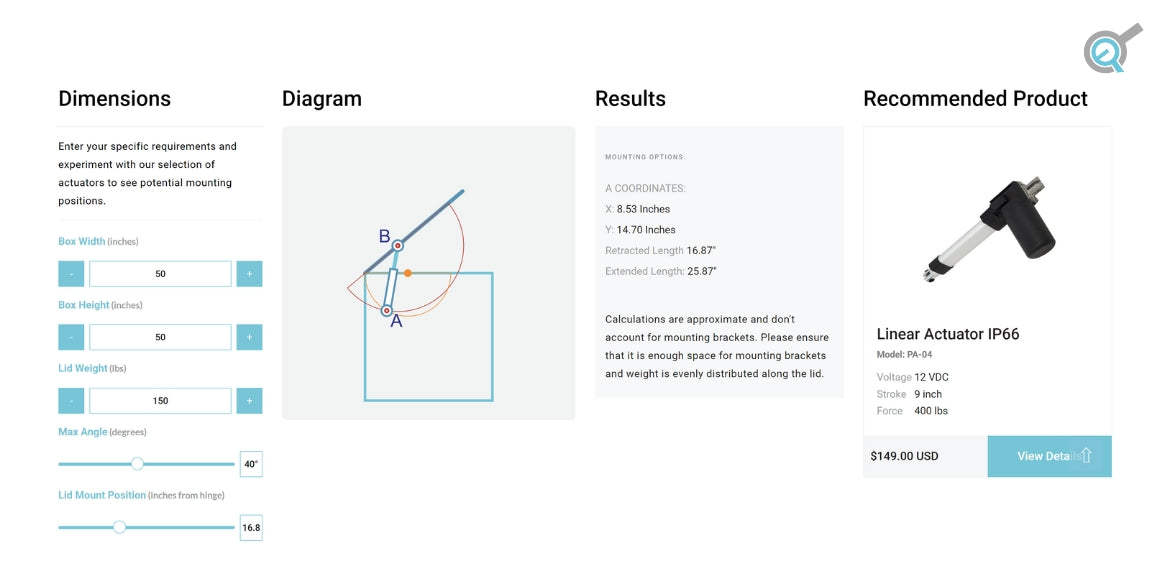

Physical Dimensions

Before installation, it is important to check if a given space can accommodate an actuator’s length, width, and height. An actuator’s retracted hole to hole (H2H) dimension is the first crucial measurement when determining its physical requirements. This measurement is the distance from the center of the rear mounting hole to the center of the front mounting hole. It is essential to make sure that this dimension lines up with your application’s rear mounting hole center to the front mounting hole center. Our industrial linear actuators come in a range of different sizes, from the compact PA-09 Mini Industrial Actuator to our largest PA-100 solar tracker linear actuator depending on the scale you need for your heliostats.

Single-Axis VS Dual-Axis

A single-axis heliostat tracker moves the mirrors in only one direction, typically from east to west, following the sun's path throughout the day. Dual-axis heliostat tracker can move the mirrors horizontally (east to west) and vertically (up and down), allowing the mirrors to track the sun's position not only throughout the day but also throughout the year for greater overall efficiency. Single-axis trackers are simpler and less expensive than dual-axis trackers, however, dual-axis trackers offer greater efficiency throughout the year.

The choice between single-axis and dual-axis trackers generally depends on factors such as the specific solar power system requirements, available space, budget, and desired energy output. Single-axis trackers are usually suitable for most applications and offer a good balance between cost and performance. Dual-axis trackers are typically better in situations where maximum energy output is crucial, such as concentrated solar power plants or high-efficiency photovoltaic systems. Ultimately, the decision between single-axis and dual-axis heliostat trackers should be based on a careful evaluation of your specific project requirements and cost-benefit analysis.

IN SUMMARY

Heliostats can offer several benefits as a clean and renewable energy solution to reduce our carbon footprint. When combined with industrial linear actuators, the cost-effectiveness, simplicity, and high energy generation capabilities of heliostats make them great options to consider for maximizing the use of solar power in large-scale systems.

As one of the top suppliers of electric linear actuators, Progressive Automations offers industry-leading flexibility, quality, support, and field experience to meet all your needs. If you have any other questions about what we can offer, please do not hesitate in reaching out to us! We are experts in what we do and want to ensure you find the best solutions for your application.

sales@progressiveautomations.com | 1-800-676-6123