WHAT IS SYNCHRONIZATION AND WHY WOULD YOU NEED IT?

What is synchronization? The concept is in the name: motion control devices being actuated in a ‘synchronized’ manner, and running at the exact same speed. The linear motion of multiple actuators are matched with each other to achieve complete synchronization. On the surface, synchronization can seem like an easy task. However, it can be entirely the opposite. Synchronization isn’t just achieved by wiring multiple actuators to the same switch, as many might presume – in an ideal world or a very simple setting, this might work. However, usually, it will result in multiple linear actuators moving at different speeds.

Even if two linear actuators of the same make and model are connected to the same power supply, a significant speed difference can occur if both are subjected to unequal loads, have experienced different wear and tear patterns, or are at different operating temperatures even, to mention a few problems. To achieve synchronized linear actuator movement, some form of motion control is a must. For an open-loop control system, the most popular synchronization option is a speed controller. A more sophisticated form of synchronized motion control is with a closed-loop system, which utilizes feedback from actuators to ascertain the individual needs of each device, making real-time adjustments. This form of synchronization is remarkably accurate, with no chance of error. There are multiple applications where linear actuator synchronization is a core requirement.

rešitve za linearne aktuatorje

Ponujamo vam vrsto naprednih krmilnikov in različnih vrst aktuatorjev s številnimi možnostmi prilagoditve, kar zagotavlja, da ima naša široka ponudba nekaj za skoraj vsako aplikacijo. Naj vam pomagamo najti idealno rešitev za sinhronizacijo vašega projekta!

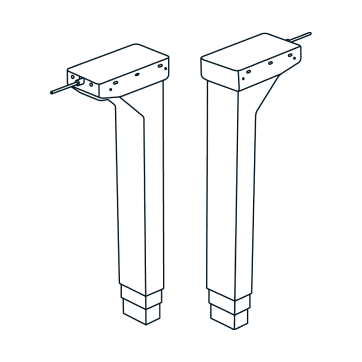

Rešitve modularnih dvižnih stebrov

Električni dvižni stebri ponujajo visoko zmogljivost, zanesljivost in varnostne funkcije, ki lahko koristijo različnim aplikacijam v skoraj vsaki panogi. Z uvedbo več možnosti prilagajanja naša izdaja modularnih dvižnih stebrov z več konfiguracijami spodbuja večjo raznolikost, ki bolje ustreza vašim potrebam!

V primeru sinhronizacije z odprto zanko, kot je krmiljenje več aktuatorjev s krmilno omarico PA-28 ali z lastno programirani mikrokrmilniki, morate zagotoviti, da so regulatorji hitrosti sposobni upravljati sistem. Na voljo mora biti dovolj pinov, da se prilagodi število aktuatorjev, ki jih uporabljate, koda pa mora biti brezhibna. Ko z uporabo zaprtozančne povratne zanke Pri sistemih je najpomembnejši dejavnik, ki ga je treba upoštevati, vrsta dajalnika povratne zveze, integriranega v vaše sinhronizirane aktuatorje. V tem pogledu sta povratna zveza Hallovega efekta in povratna zveza potenciometra na vrhu seznama.

In Hall effect linear actuators, like the ones shown on this page, the feedback encoder records the number of revolutions the actuator’s driving motor is going through while moving. From this information, it is very easy for the controller to calculate the exact position, and hence the speed, of the actuator’s rod. The encoders of all the linear actuators are constantly sending feedback to the controller, which determines which actuator(s) is lagging or speeding up, and then adjust their respective speeds accordingly to ensure smooth, synchronized movement. When using Hall Effect actuators, it is necessary to use a compatible controller as well. You cannot use them with any ordinary controller, instead, one that is designed for this specific purpose is required. The control box must also have the desired number of channels in accordance with the number of actuators being used. Potentiometer feedback works in a similar way. As the actuator’s rod moves in and out, the potentiometer’s electrical resistance changes with it proportionately. This information is transmitted to the controller, which then performs the exact same function as explained above to synchronize actuators.

While many of our actuators can be customized to include feedback options (just check their data sheet), we also have stocked options!

Starting with our linear actuator range, we have high-performing Hall effect actuators with 12 VDC and 24 VDC variants. For example, our PA-04-HS linear actuator comes installed with a built-in Hall effect sensor that enables synchronization. Customers can also choose between 12 VDC and 24 VDC power supply options. The 12 VDC power supply linear actuators are much more common as most power supplies are of this specification. They are easier to integrate into actuation systems and pack decent performance specifications. The 24 VDC actuators need a specialized power supply, which often requires additional investment and equipment.

Vendar pa te različice lahko zagotovijo več moči in navora, imajo manjšo porabo toka in tanjše zahteve glede ožičenja, kar odlično nadomesti zgoraj omenjene pomanjkljivosti. Ne glede na vašo izbiro, Progressive Automations poskrbi, da je krmiljenje več aktuatorjev vredno vaše naložbe. Za sinhronizacijo ponujamo večkanalne krmilne omarice, ki so zasnovane za upravljanje aktuatorjev na podlagi povratne zanke, vključno z našo serijo krmilnih omaric PA-40 palec FLTCON. Ti krmilniki, zasnovani za aktuatorje s Hallovim efektom, lahko delujejo z aktuatorji z 12 palec 24 VDC. PA-40, pravzaprav je specializirana sinhronizacijska rešitev za aplikacije z dvojnim Hallovim efektom.