"Why won't this work?" "What am I doing wrong" - We hear this a lot!

Before you start modifying your actuator, which we have carefully designed and manufactured for you, take a few minutes and read our blog on how to configure an Actuator system.

Selecting an Appropriate Actuator

Progressive Automations provides a wide selection of actuators that are suitable for many industries. This means that we have tried to cater to as many different applications as we can, but this can lead to a lot of confusion when surfing through our website. First, we will discuss the basics, then a few solutions to a common issue many of our customers experience.

Understanding Actuator Specifications

When selecting an actuator, there are a few key considerations that you should keep in mind such as the following.

- Force

- Speed

- Stroke

- Environment conditions

- Power requirements.

The force rating of an actuator refers to the maximum amount of force that the actuator is capable of pushing/pulling (dynamic) and holding (static). Keep in mind that the weight of the object in question may not be the force that is exerted onto the actuator. Uneven distribution of weight, actuators that are not perpendicular to the motion of the object, and relative position of the actuator to the center of mass are all examples of when the actuator may experience more (or less) force than the weight of the object.

How fast are you wanting your object to extend/retract? If you know that you want your object to move 10 inches in 4 seconds, simply divide the distance by the time to get a speed of 2.5”/sec. In order to do so, you need to figure out how far you want to move the object!

Have you considered dust or moisture in your environment? Our actuators have Ingress Protection ratings that state their resistance against these two things. Refer to our blog “What is an IP Rating “for more information on protection against dust and water.

When considering the voltage and current requirements of your actuator, you should know that our actuators are either 12VDC or 24VDC (Volts Direct Current). The current ratings range from 4A to 20A which means that when you are selecting a control system and power supply, you must consider this! We will discuss this later on.

Avoiding Unnecessary Current Draw

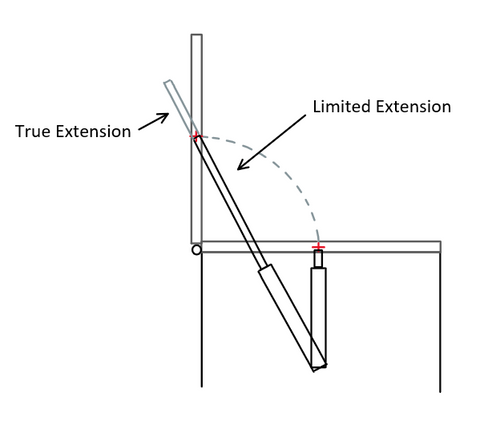

In many applications, there may be cases where the motion of the actuator is not limited by the full stroke of the rod, but rather the application itself. For example, opening a hinged lid with a linear actuator can prevent the actuator to trigger the end limit switches if the proper stroke size is not selected and the actuator is not mounted properly (Fig. 1). In these cases, the motor thinks more power is necessary to be able to reach its final destination and continues to draw current. This over-draw of current may exceed the current rating of the actuator and damage the motor.

Figure 1: True vs. limited extension

Using the hinged lid example, if you mount the actuator close to the hinge, it will require much more force to open the lid than having the actuator mounted at the end. You can refer to the blog "How to Mount A Linear Actuator Efficiently" to get more information on the effects of gravity and angle of orientation.

Selecting the Appropriate Control Box and Power Supply

As mentioned previously, our actuators are either 12VDC or 24VDC. This means that for most home projects you will need a power converter that is capable of converting 120VAC (volts Alternating Current) of your wall outlet (in North America) to your actuator voltage. Our FLTCON control boxes have the capability of doing so in addition to receiving Hall Effect signals. Otherwise, our power supplies are designed to specifically convert voltages from your wall outlet to your actuator. In addition, make sure to check the current ratings for your actuator(s) and select a control box and/or power supply that is rated for the total current rating of your actuators!

If Hall feedback option is what you are after then you can look at our hall effect compatible control boxes.

Now that we have gone over the basics of an actuator system and common issues, you are now ready to reach out to us to make a purchase or use our website!

We are always happy to answer any questions you might have so feel free to give us a call at 1-800-676-6123 or email us at sales@progressiveautomations.com.