Connected medical devices in medical and laboratory equipment within hospital settings and home care present new challenges for manufacturers, with increased diversity and performance capabilities required. Find the ideal solution for medical and laboratory equipment in our specialized medical actuator range.

LINEAR MOTION FOR MEDICAL & LAB EQUIPMENT

Designed to deliver smooth and reliable performance in many healthcare applications.

2.41%

Average YoY Cost Reduction99.8%

Perfect QC Pass Rate100%

Powered By Renewable EnergyOEMs: Working with Progressive Automations

The list of requirements for modern machinery in agriculture is increasing. The cross field between delicate precision farming and custom.

Consistently High Product Quality

Get ultra-low product failure rates with a quality control regime that's reliable, stringent, adaptive and systematic.

Progressive Automations is ISO9001.2015 Certified

Get quality you can trust. Work with a partner that's truly committed to continuous improvement.

We Deliver on Time, Every Time.

Even with supply chain challenges becoming more common, we've maintained a 98% on-time shipment rate since 2017.

Flexible Pricing that’s Dynamic

Unlock savings with ramp-up friendly, inflation-resistant pricing, where scale-related savings pass directly on to you.

Zero Lead Times & Unparalleled Flexibility with Smart Logistics

Avoid costly air freight and production delays. We get custom units to your dock in days, not months.

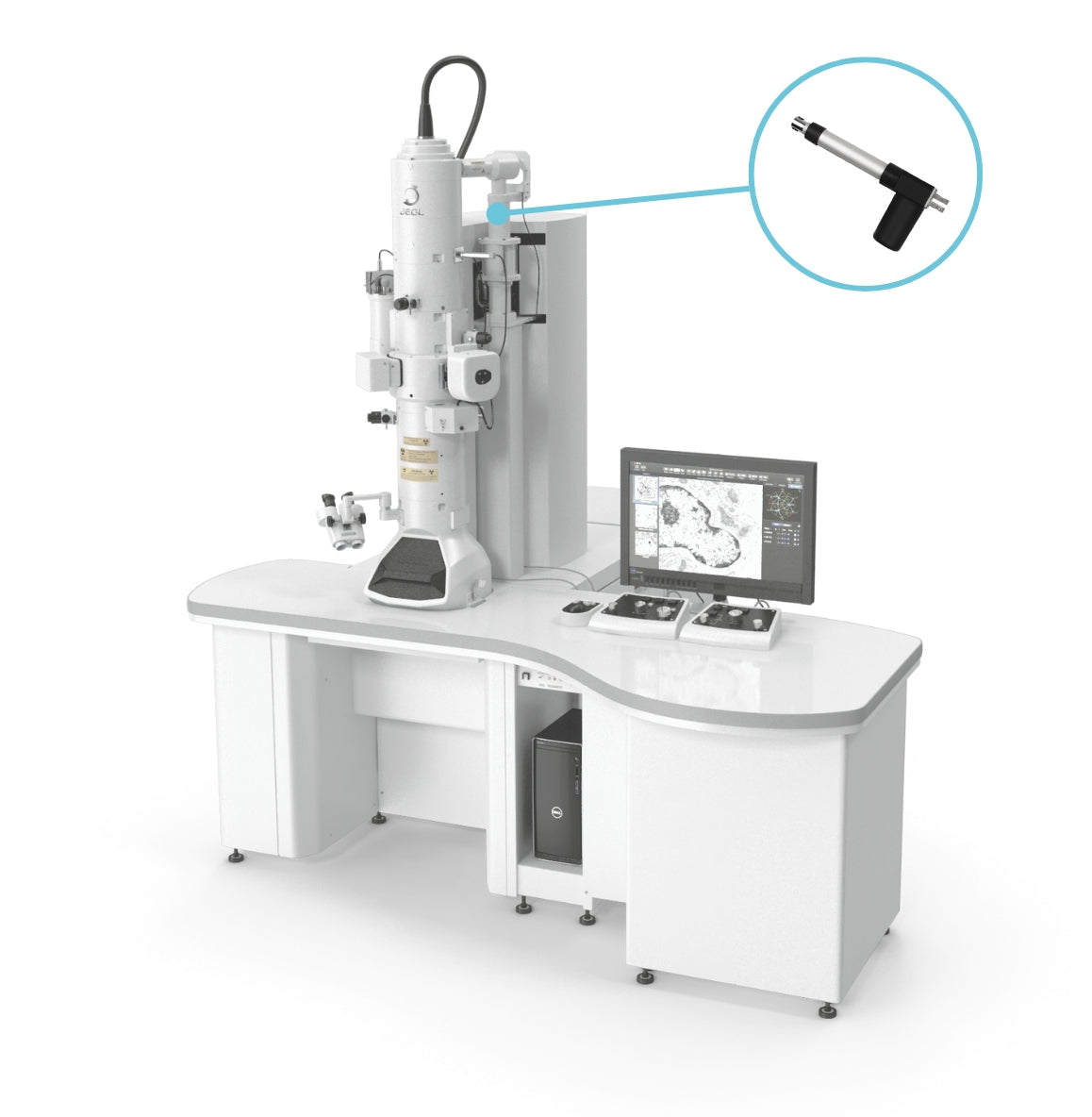

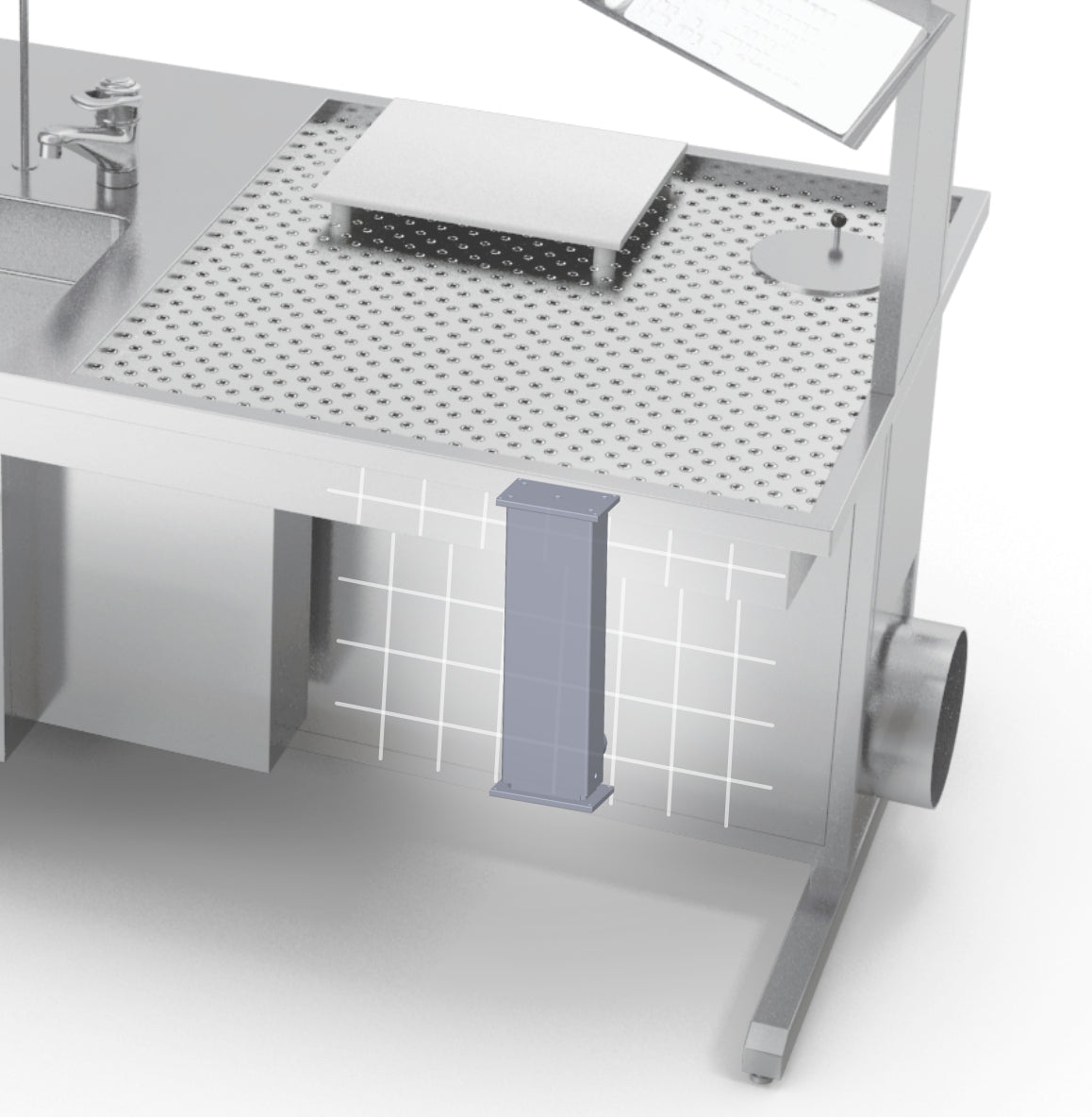

Linear actuators in laboratory equipment allow for precise control of instruments and sample handling. They operate quietly and meet strict laboratory standards, enhancing the accuracy and efficiency of scientific research.

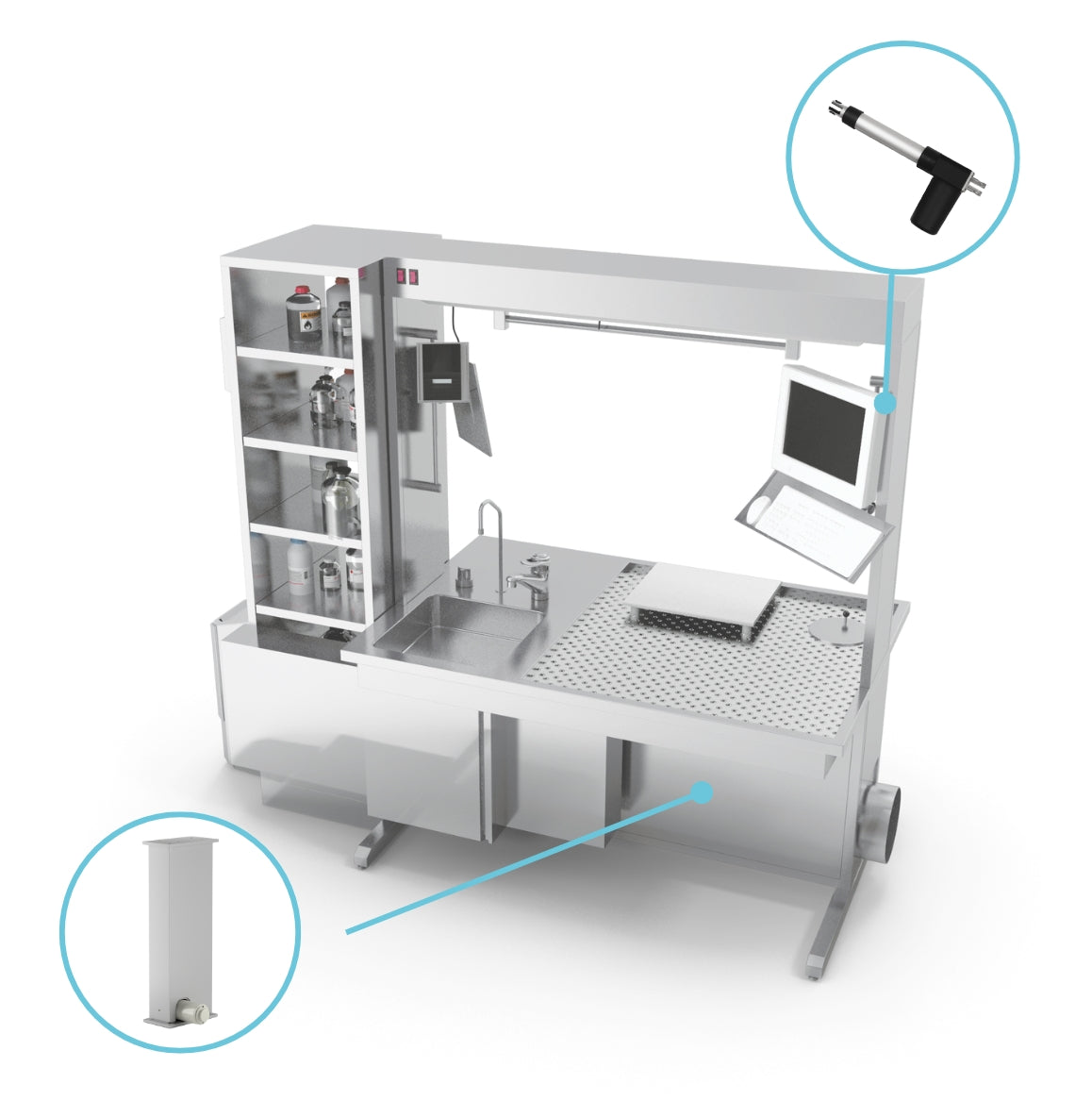

Linear actuators in medical workstations facilitate ergonomic adjustments to height and orientation, ensuring comfort and accessibility for healthcare professionals during long shifts. They operate quietly and adhere to medical safety standards, optimizing the workspace environment.

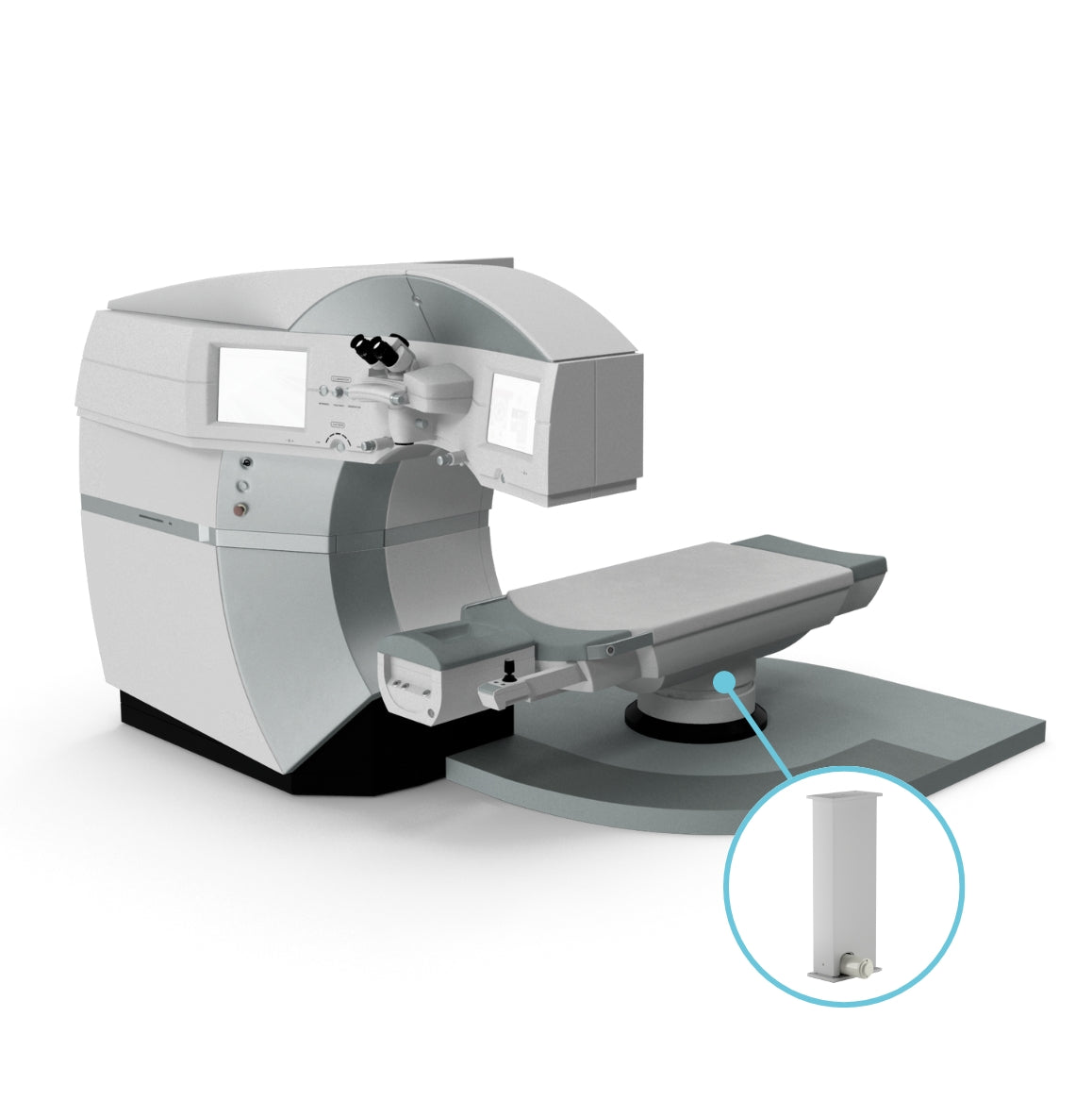

In ophthalmic equipment, linear actuators enable precise positioning of diagnostic tools for eye examinations. They ensure smooth and quiet operation, critical for the sensitive nature of eye care and patient comfort.

Linear actuators in various medical devices provide essential motion control for therapeutic and diagnostic applications, enhancing device functionality and patient treatment outcomes. They operate with precision and reliability to adhere to stringent medical standards.

Linear actuators in mammography units adjust the compression and positioning of the imaging equipment, crucial for obtaining clear and accurate breast images. They ensure quiet and smooth adjustments, minimizing discomfort for patients during sensitive procedures.

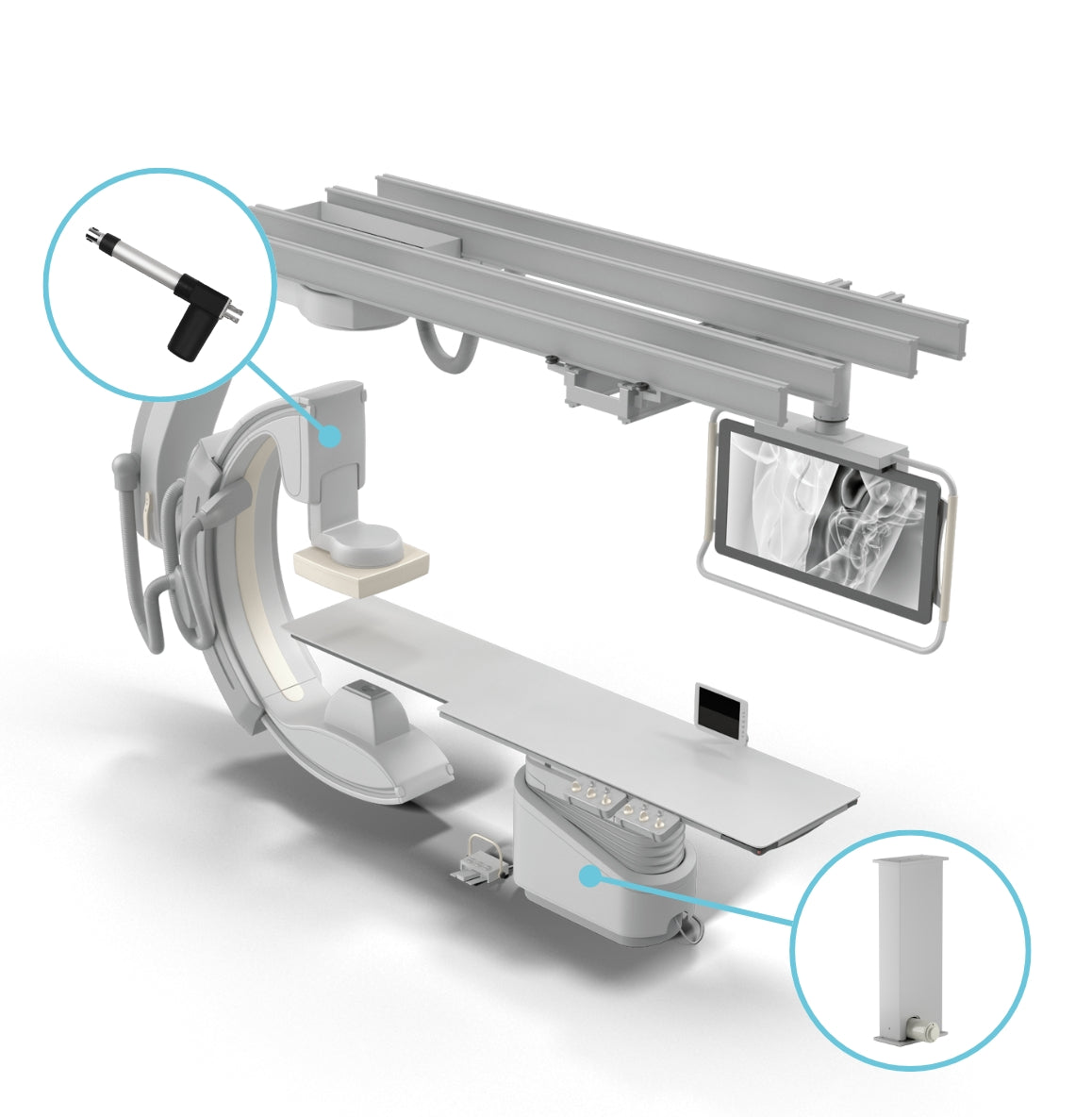

Linear actuators in X-ray equipment facilitate precise movements and positioning of the machinery, ensuring optimal imaging angles and patient safety. They operate quietly and meet radiological safety standards, essential for diagnostic accuracy.

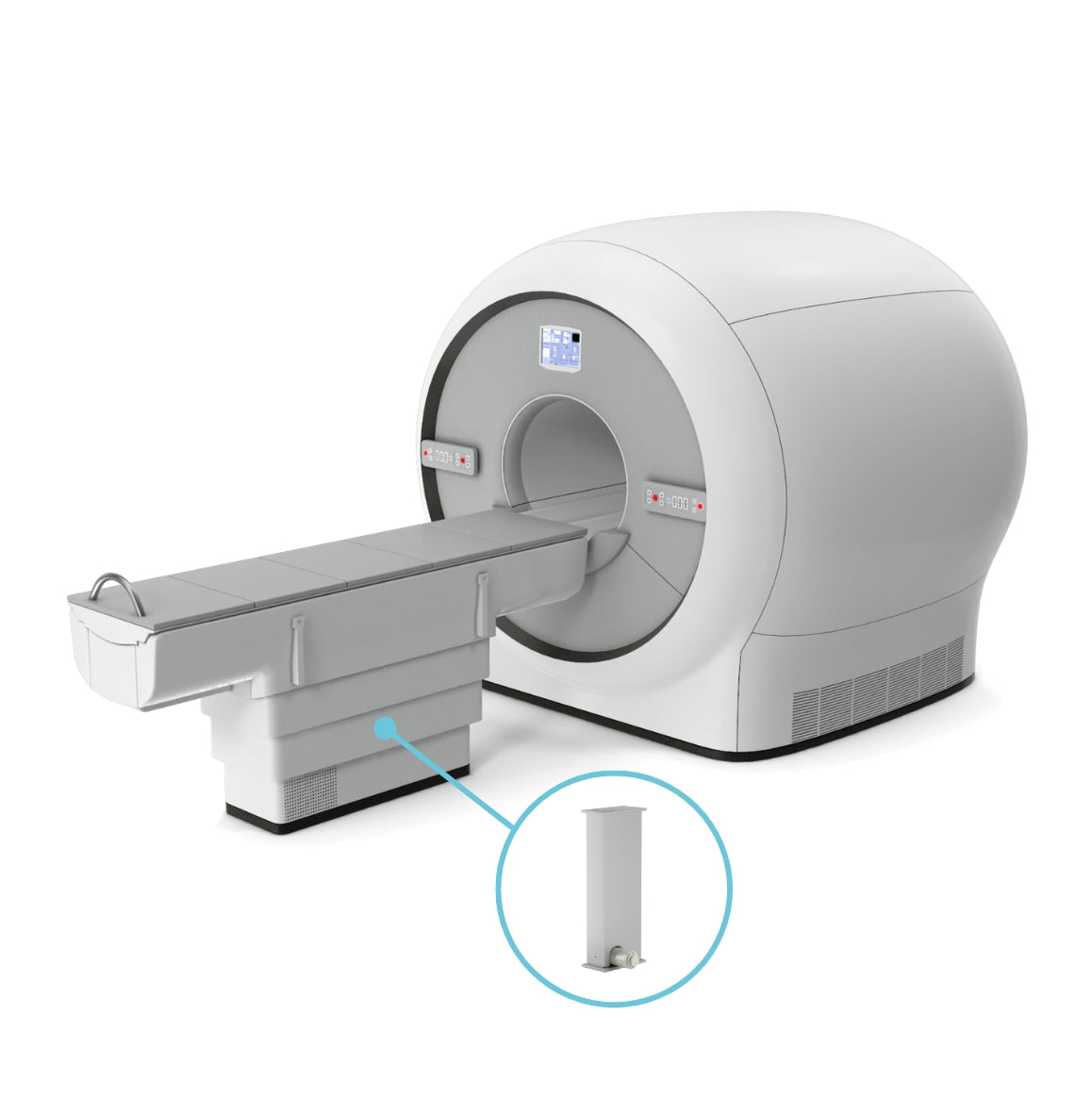

Linear actuators in MRI machines adjust patient beds and equipment settings, enhancing the precision of imaging and patient comfort during scans. They are designed to operate without interfering with magnetic fields and maintain quiet, smooth movements.

Linear actuators in incubators adjust temperature, humidity, and positioning controls, providing a stable and controlled environment for neonatal care. They operate quietly and adhere to stringent medical standards, ensuring the safety and well-being of infants.

TESTIMONIAL

"Progressive offers off-the-shelf units and custom options that could match our needs better while accommodating a faster turnaround time”

Jett Rubin Medical Device Manufacturer

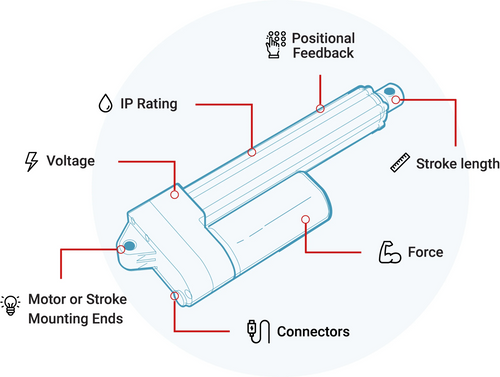

Custom Linear Motion for Medical & Lab Equipment

Actuator Customization

Transform your projects with actuators built for your unique challenges. Whether you're transitioning from hydraulics or facing issues like water ingress, we understand that every application is unique.

Our engineers help you craft solutions that fit your exact specifications, with flexible minimum quantities, turning complex requirements into precise, efficient designs.

As your needs evolve, so do our solutions - we're here for the long haul, and you're gaining a partner dedicated to your success.

Case Studies

CASE STUDY

UV Hammer for Dimer

Dimer UV are experts in inventing cutting-edge germicidal UV light disinfection systems. The company's mission is to set new, higher standards for public health in transportation and shared spaces.

When developing the UV Hammer, Dimer needed to find the right linear actuator to maneuver the unit’s UVC wing assembly. Other suppliers Dimer worked with in the past were not only more expensive and less reliable, but also unwilling to troubleshoot issues when they arose. From there, Dimer turned to Progressive Automations.

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

Insights

Blog post

Precision in Motion: How to Choose Linear Actuators for Modern Medical Devices

Blog post

Precision in Dialysis Chairs: The Role of 12V Electric Linear Actuators

Blog post

Designing for Improved Care: Innovations and Features in Medical Tables

Blog post

440 Stainless Steel: The Ultimate Guide to High-Performance Martensitic Steel

Blog post

Micro Linear Actuators: Revolutionizing Precision in Medical Devices

Blog post

Revolutionizing Healthcare: The Impact of Miniaturization and Linear Actuators in Medical Equipment

Blog Post

Download The Testing Guide

This guide will outline essential steps and the process of evaluating a sample actuator. We include a checklist to ensure all the requirements are met.

Blog Post

Top 10 Questions We Get from Our OEM Customers

You will find useful FAQ from OEM Customer as for your search for a parts supplier of electric linear actuators.

Application

Laboratory Equipment

Linear actuator ability to precisely adjust and control various parameters is indispensable for experiments that require exact conditions.

Challenges

Variations in load during equipment operation require actuators to adapt to different weight distributions. Integrating linear actuators into complex laboratory systems while ensuring compatibility with existing control systems and components can also be challenging. Environmental factors like temperature fluctuations and humidity levels can adversely affect actuator performance. Safety and redundancy are paramount to prevent accidents and ensure the safety of laboratory personnel and equipment.

Solutions

Advanced feedback control are used to enhance motion accuracy, ensuring precise control over laboratory operations. Force sensors and adaptive control strategies adjust actuator output in real-time based on load changes, accommodating varying operational demands. Optimizing actuator design for high-speed operation and incorporating dynamic control improve response times and dynamic performance. Standardizing communication protocols and employing modular design approaches streamline integration processes, facilitating seamless compatibility with laboratory systems. Robust materials and high IP Ratings are employed to withstand environmental challenges and maintain reliable operation. Safety is enhanced through redundant actuator systems and fail-safe mechanisms like brake systems and position sensors.

Benefits

Enhanced precision and control improve the accuracy and repeatability of scientific experiments and processes. Adaptive load management ensures that equipment can handle varied operational demands efficiently. Improved dynamic performance facilitates rapid testing cycles and more efficient laboratory workflows. Seamless integration with control systems enhances usability and reduces setup times. Robust construction and environmental protection extend the lifespan of actuators, reducing operational costs and downtime. Enhanced safety features protect laboratory personnel and valuable experiments.

Laboratory Equipment

Arm Positioning

Model

PA-04 Linear Actuator

Function

Linear actuators adjust the positioning of analytical instruments, optical components, and sensors.

Benefits

Allows researchers to optimize experimental setups and data acquisition processes, improving the quality of experimental data.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Medical industries.

Key Features

- Versatile Load Capacity

- Hall Effect Feedback Options

- Smooth Reliable Motion

- High Speed

- Maintenance Free

- IP66 Water Protection

Request Custom Specs

Application

Medical Workstations

Linear actuators ability to deliver precise, stable, and quiet adjustments tailored to the specific needs of healthcare environments makes them indispensable for modern medical facilities.

Challenges

Achieving precise and accurate control over workstation components like monitor arms or keyboard trays is crucial for user comfort and effectiveness. Managing varying loads from different equipment weights without compromising performance poses a significant challenge. Space limitations within medical workstations require compact actuator designs. Integrating actuators seamlessly into existing mechanical and electrical systems, including control interfaces and power management, can be complex. Minimizing noise during actuator operation is necessary to maintain a quiet working environment. Safety features must be incorporated to prevent accidents. User interfaces need to be intuitive and ergonomic to meet the diverse needs of healthcare professionals.

Solutions

Advanced feeedback control ensure precise positioning and smooth movement of workstation components. Load sensors and adaptive control strategies dynamically adjust actuator output based on real-time load changes, enhancing stability and performance. Compact linear actuators with space-efficient mounting options are designed to maximize space utilization within workstations. Standardized communication protocols and interface connectors simplify integration with existing systems, ensuring compatibility and ease of installation. Noise-dampening materials are employed to minimize operational noise, creating a more conducive working environment. High-quality materials enhance the durability and reliability of actuators. Safety mechanisms such as overload protection, limit switches, and emergency stop functions are integrated to mitigate risks.

Benefits

Precise control over workstation adjustments leads to better ergonomics, reducing strain and increasing comfort for healthcare professionals. Adaptive load management ensures optimal performance and stability, accommodating various equipment configurations. Compact and efficiently integrated actuators preserve valuable workspace while maintaining full functionality. Reduced noise levels contribute to a quieter, more comfortable working environment, which is crucial in healthcare settings. Enhanced durability and reliable operation reduce maintenance needs and ensure continuous use without failures. Advanced safety features provide essential protection for users, preventing injuries and accidents.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductMedical Workstation

Height Adjustment

Model

LG-12 Lifting Column

Function

Control the height adjustment of workstation surfaces.

Benefits

Allows users to switch between sitting and standing positions to reduce sedentary behavior, improve circulation, and alleviate musculoskeletal strain during work tasks.

Medical Workstation

Monitor Arm Adjustment

Model

PA-04 Linear Actuator

Function

Control the height adjustment of monitor arms.

Benefits

Allows users to fine tune the distance between the workstation surface and monitor viewing height to reduce back and neck pain.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Medical industries.

Key Features

- Versatile Load Capacity

- Hall Effect Feedback Options

- Smooth Reliable Motion

- High Speed

- Maintenance Free

- IP66 Water Protection

Request Custom Specs

Request Custom Specs

Application

Ophthalmic Equipment

Linear actuators ability to precisely adjust optical components enhances the functionality and effectiveness of eye care, making them indispensable in the field of ophthalmology.

Challenges

Achieving precise motion control is crucial for the accurate positioning of optical components like lenses and mirrors. Managing load variations during procedures is also challenging, as different optical components exert varying forces on the actuators. Dynamic performance requirements such as rapid acceleration and deceleration are necessary for quick adjustments during scanning or imaging procedures. Environmental factors like temperature and humidity can adversely affect actuator performance.

Solutions

High-resolution encoders and advanced feedback control algorithms are implemented to enhance motion accuracy, ensuring precise alignment and focusing capabilities. Force sensors and adaptive control strategies adjust actuator output in real-time based on load changes, maintaining consistent performance and stability. Optimizing actuator design for high-speed operations and implementing dynamic control algorithms improve responsiveness, crucial for rapid procedural adjustments. Standardizing communication protocols and utilizing modular design approaches simplify the integration process, ensuring seamless operation within ophthalmic systems. Robust materials and protective coatings, along with advanced sealing techniques, protect actuators from environmental stress, enhancing durability and reliability. Redundant actuator systems and fail-safe mechanisms such as brake systems and position sensors are integrated to enhance safety, preventing equipment damage and ensuring continuity during critical procedures.

Benefits

Enhanced precision in motion control improves the accuracy of diagnostic and therapeutic procedures, directly impacting patient outcomes. Adaptive load management ensures stability and performance consistency, critical during delicate eye examinations. Faster response times enable efficient and effective patient care, essential in fast-paced clinical environments.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductOphthalmic Equipment

Height Adjustment

Model

LG-12 Lifting Column

Function

Height adjustment of ophthalmic equipment.

Benefits

Allows practitioners to customize the equipment height to accommodate patients of different heights, ensuring comfort and optimal positioning for eye examinations.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

Request Custom Specs

Application

Medical Devices

Linear actuators are crucial in medical devices, providing essential motion control that enhances patient care, improves operational efficiency, and ensures safety across various medical applications.

Challenges

Meeting dynamic performance requirements, such as rapid acceleration and deceleration, is essential for responsive device behavior. Integrating actuators into medical devices while ensuring compatibility with existing control systems involves complex engineering. Safety and redundancy are paramount to protect patients and healthcare professionals in case of actuator failure. Environmental factors like temperature and humidity can impact actuator performance and longevity. Maintenance and serviceability are crucial to minimize downtime in critical medical settings. Noise reduction is necessary to maintain a calm environment for patients. Ensuring actuator fall within the space limitations of compact medical devices are additional challenges.

Solutions

High-resolution feedback control algorithms are used for precise motion control. Load sensors and adaptive control strategies dynamically adjust to changing loads. Actuator designs optimized for high-speed operation improve dynamic performance. Standardized communication protocols facilitate seamless integration. Redundant safety systems and fail-safe mechanisms enhance reliability and safety. Durable materials and high IP Rating, coupled with advanced sealing techniques, mitigate environmental impacts. Noise-dampening materials and vibration isolation enhance comfort. Compact actuator designs and space-saving configurations maximize utilization in tight spaces. Thermal management systems regulate temperature, while high-quality materials reduce wear and tear. Materials resistant to sterilization processes maintain hygiene standards. Compliance with regulatory standards, such as Salt Spray Test Certification, or ISO 13485, and IEC 606011.

Benefits

Precise control and load management enhance device performance and patient comfort. Rapid response capabilities and seamless system integration boost operational efficiency. Enhanced safety features and robust designs ensure reliability in demanding medical environments. Reduced noise and energy-efficient operation contribute to more sustainable and patient-friendly healthcare settings. Improved maintenance features and adaptability to environmental conditions extend the lifespan and reduce the total cost of ownership. Compliance with regulatory standards and adaptability to patient needs further validate the utility and effectiveness of these systems.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductMedical Devices

Height Adjustment

Model

LG-12 Lifting Column

Function

Lifting columns adjust the height of the various medical instruments.

Benefits

Allows medical workers optimal height, improving ergonomics and reducing fatigue.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

Request Custom Specs

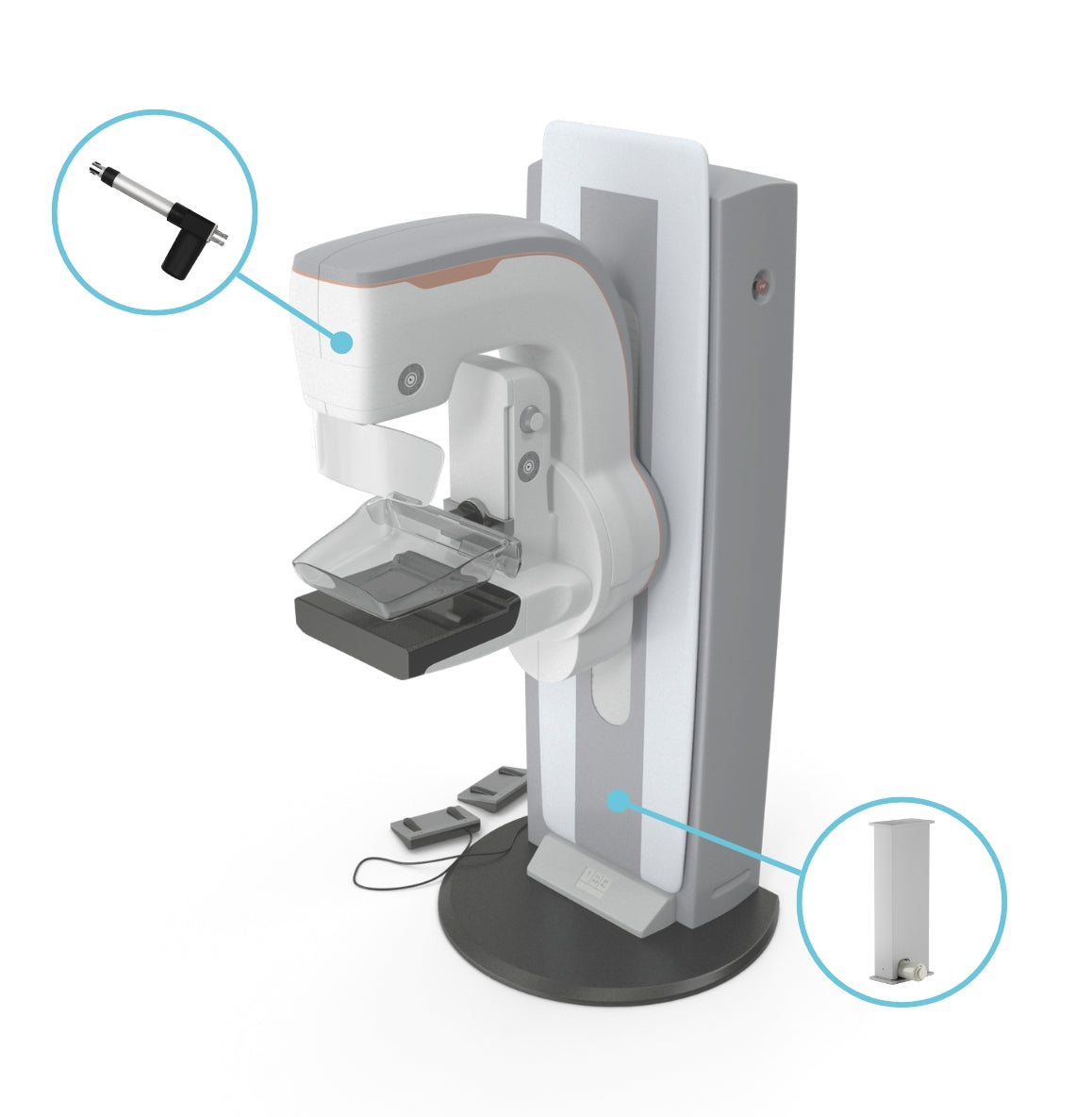

Application

Mammography

Linear actuators are crucial in mammography machines, providing the necessary motion control that enhances the accuracy and reliability of breast imaging.

Challenges

Maintaining stable and vibration-free motion control during imaging is crucial to minimize errors and ensure diagnostic accuracy. Integrating actuators into complex mammography systems while ensuring compatibility with control systems. Ensuring the safety of patients and healthcare professionals during examinations is paramount, necessitating reliable safety features in actuators. Cleaning needs can adversely affect actuator performance and durability. Additionally, performing maintenance and servicing on actuators can be challenging due to the confined and complex nature of mammography machines.

Solutions

Advanced feedback control are employed to enhance positioning accuracy, ensuring precise alignment of imaging components. Damping mechanisms are utilized to maintain stable, vibration-free motion during imaging procedures. Adaptive control strategies and load sensing technologies dynamically adjust actuator output in real-time based on load changes, ensuring consistent performance. Standardized communication protocols allow for seamless integration with mammography systems. Safety features such as overload protection and emergency stop mechanisms are incorporated into actuators to enhance safety and prevent accidents. Robust materials and high IP ratings are used to withstand environmental challenges, enhancing durability and reliability. Also, medical standards compliance such as IEC 60601-1 ensures the safety of patients and healthcare professionals during device operation.

Benefits

Enhanced precision in positioning improves the accuracy of diagnostic images, reducing the likelihood of misdiagnoses and the need for repeat scans. Stable motion control during imaging reduces errors, ensuring higher-quality images and more reliable diagnostics. Adaptive load management maintains optimal performance, accommodating various patient sizes and conditions. Improved integration capabilities reduce technical challenges and streamline mammography operations. Enhanced safety features protect both patients and operators, fostering a safer examination environment. Durable actuators reduce maintenance needs and withstand challenging environmental conditions to extend the lifespan of the equipment.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductMammography

Arm Positioning

Model

PA-04 Linear Actuator

Function

Lifting actuators adjust the height of the mammography X-ray source unit.

Benefits

Allows for optimal alignment with patients of varying heights, ensuring accurate imaging and enhancing patient comfort.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Medical industries.

Key Features

- Versatile Load Capacity

- Hall Effect Feedback Options

- Smooth Reliable Motion

- High Speed

- Maintenance Free

- IP66 Water Protection

Request Custom Specs

Request Custom Specs

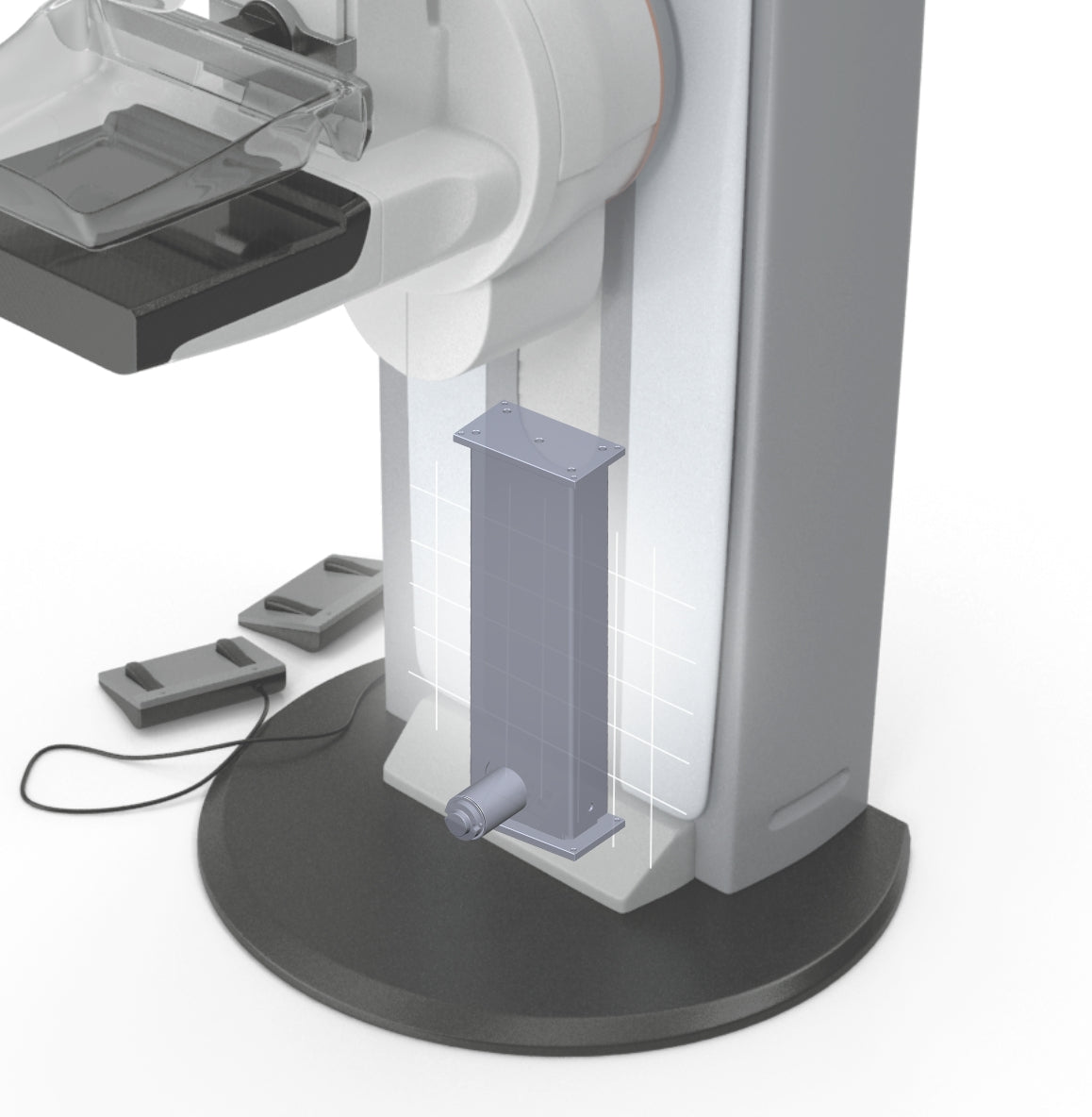

Mammography

Height Adjustment

Model

LG-12 Lifting Column

Function

Raises and lowers to control the height adjustment of the mammography unit including the support table.

Benefits

Ensures the mammography unit with the support table is positioned to the proper height to allow for proper breast support based on the user's height and body structure.

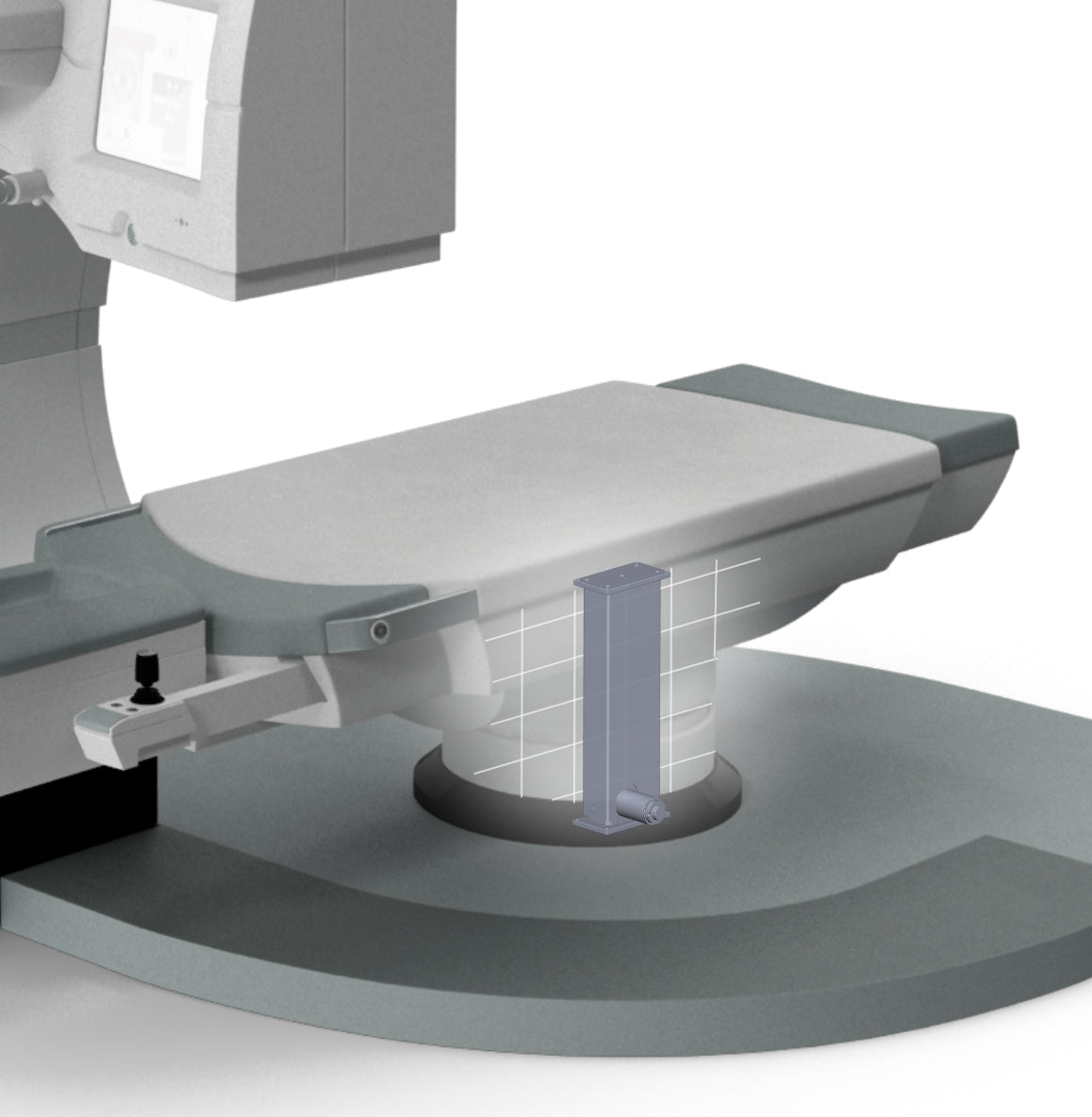

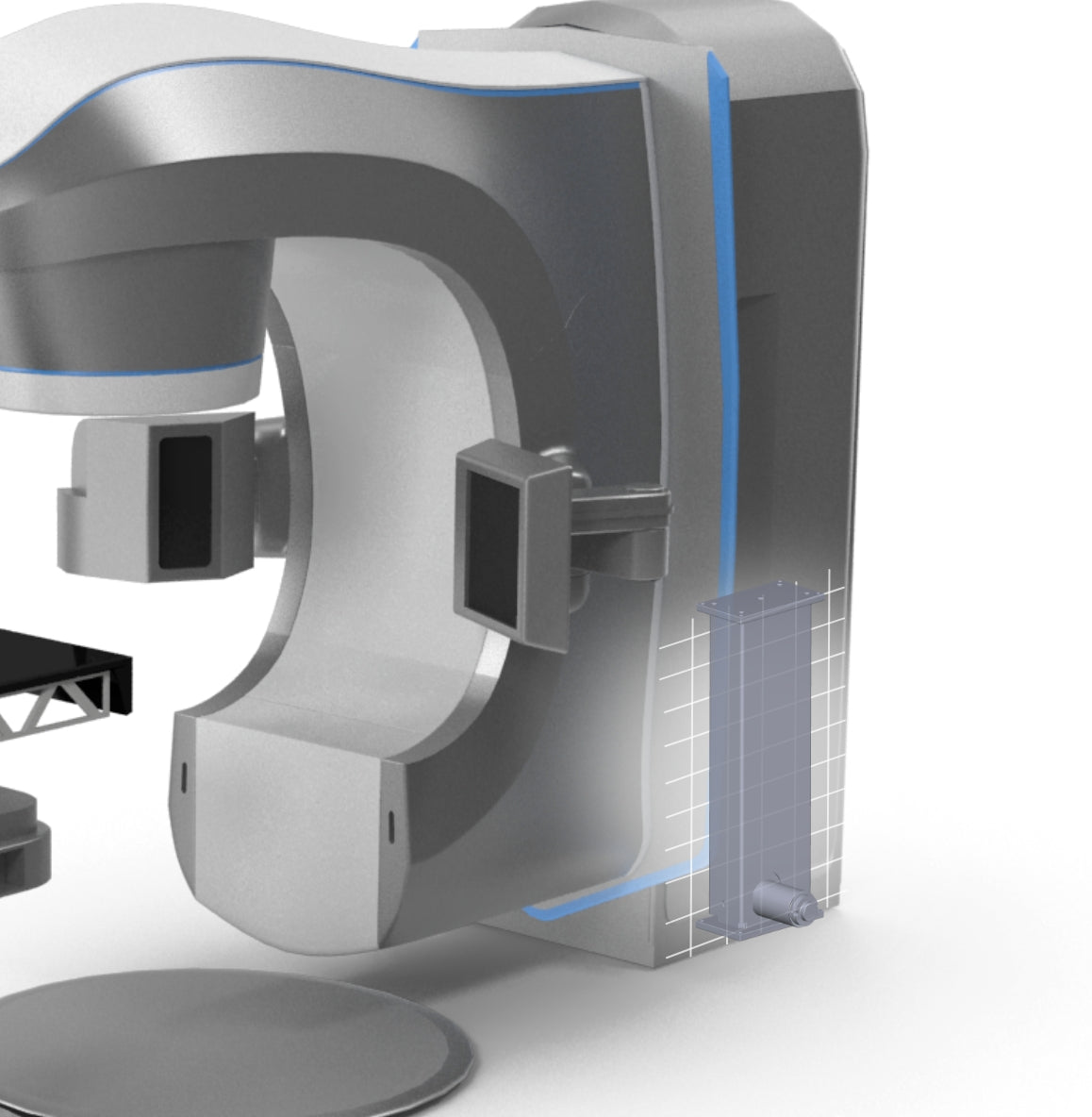

Application

X-Ray Equipment

By addressing the complex challenges of medical imaging with innovative solutions, linear actuators improve the capabilities and safety of X-ray machines, making them indispensable in modern healthcare environments.

Challenges

Rapid adjustments are necessary for efficient imaging. Handling the substantial weight of X-ray components requires actuators with high load capacities. Harsh operating environments, including exposure to dust, moisture, and electromagnetic interference, can degrade actuator. Integrating actuators with existing X-ray systems and control interfaces can pose compatibility challenges, potentially leading to communication errors. Excessive noise and vibration during operation can interfere with imaging quality and patient comfort. Ensuring the safety of operators and patients is paramount, but unexpected movements or mechanical failures can pose significant safety risks.

Solutions

High-precision feedback systems, minimize positioning errors, enhancing the accuracy of component adjustments. Optimizing actuator design and control enhances the dynamic response of actuators, reducing settling time and overshoot for more rapid and accurate positioning. Actuators designed with robust materials and mechanisms withstand heavy loads while maintaining stability and precision. Protective measures like IP-rated enclosures, corrosion-resistant coatings, and electromagnetic shielding safeguard actuators from harsh environmental factors. Ensuring compatibility with commonly used communication protocols and providing versatile mounting options facilitate seamless integration with various X-ray system configurations. Noise-reducing technologies such as precision machining, vibration dampening materials, and advanced motion control algorithms minimize operational noise and vibration, improving imaging quality and patient comfort. Implementing fail-safe mechanisms, emergency stop functions, and comprehensive testing procedures enhance safety, mitigating potential risks and ensuring reliable operation. Compliance with ISO 13485:2016 Certification in the design and manufacture of medical devices, ensures safety and efficacy.

Benefits

Enhanced precision in positioning ensures higher quality images, crucial for accurate diagnostics. Improved dynamic response allows for quicker adjustments during procedures, increasing operational efficiency. Robust actuators capable of handling heavy loads ensure stability and accuracy under various conditions. Enhanced environmental protection extends the lifespan of actuators and maintains their reliability in medical settings. Seamless integration and reduced noise and vibration levels enhance the overall imaging process, providing a better experience for both patients and healthcare providers. Advanced safety features protect against operational hazards, ensuring the safety of both patients and operators.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

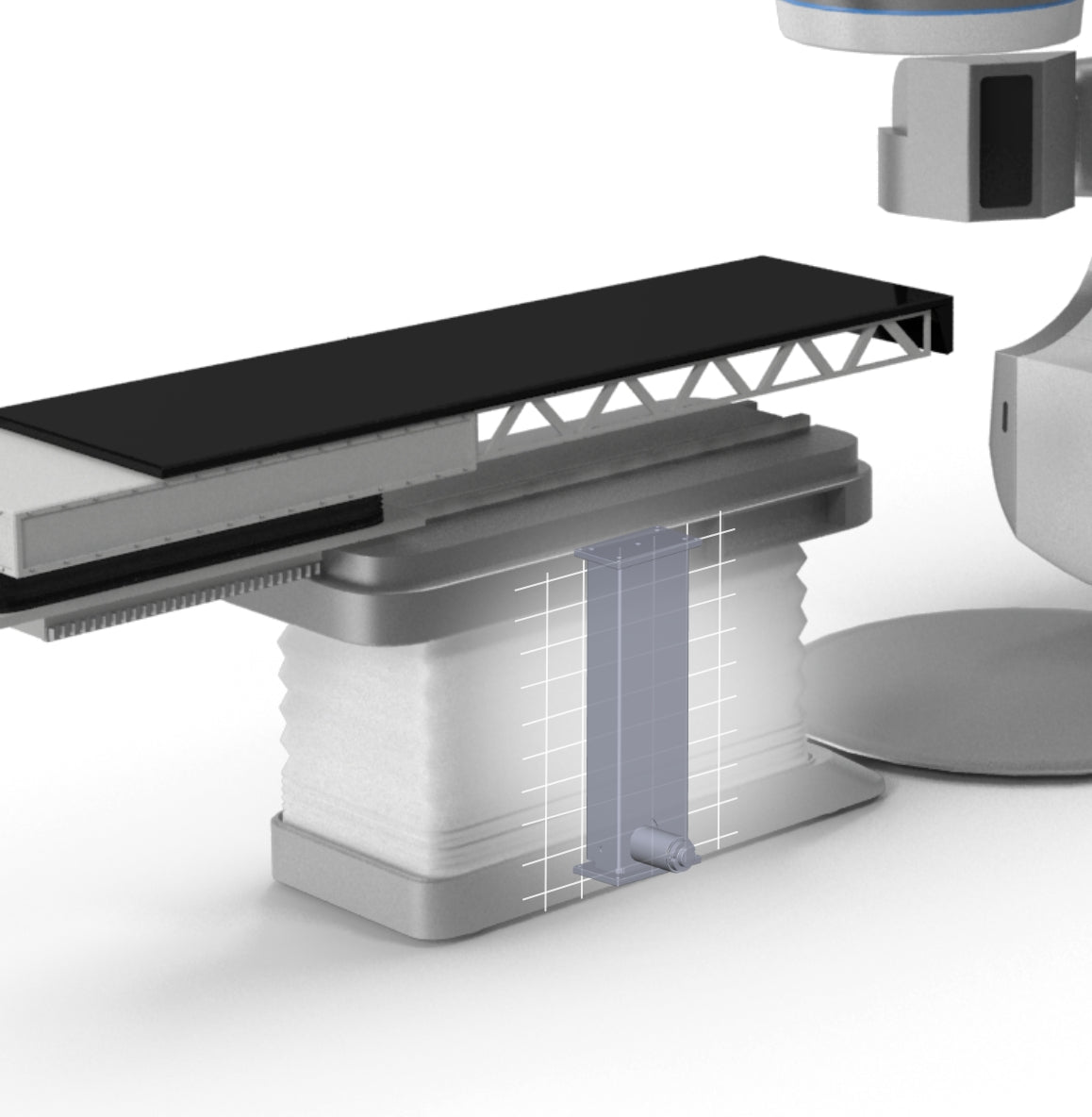

See Use Case See ProductX-Ray Equipment

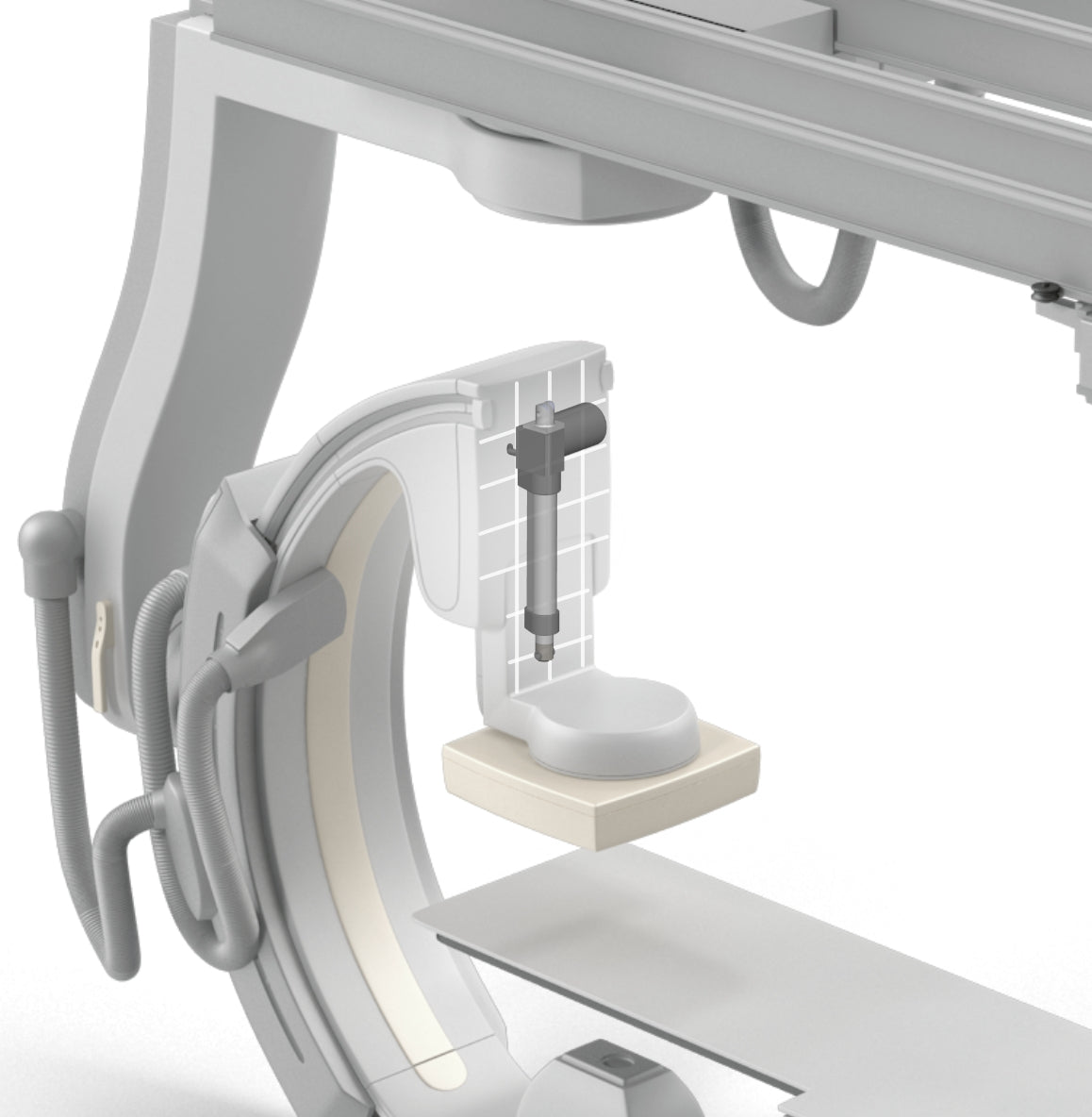

Arm Positioning

Model

PA-04 Linear Actuator

Function

Actuators adjust the position of the C-arm, both vertically and horizontally.

Benefits

Provides flexible positioning around the patient for various imaging angles, enhancing the quality and scope of diagnostic images.

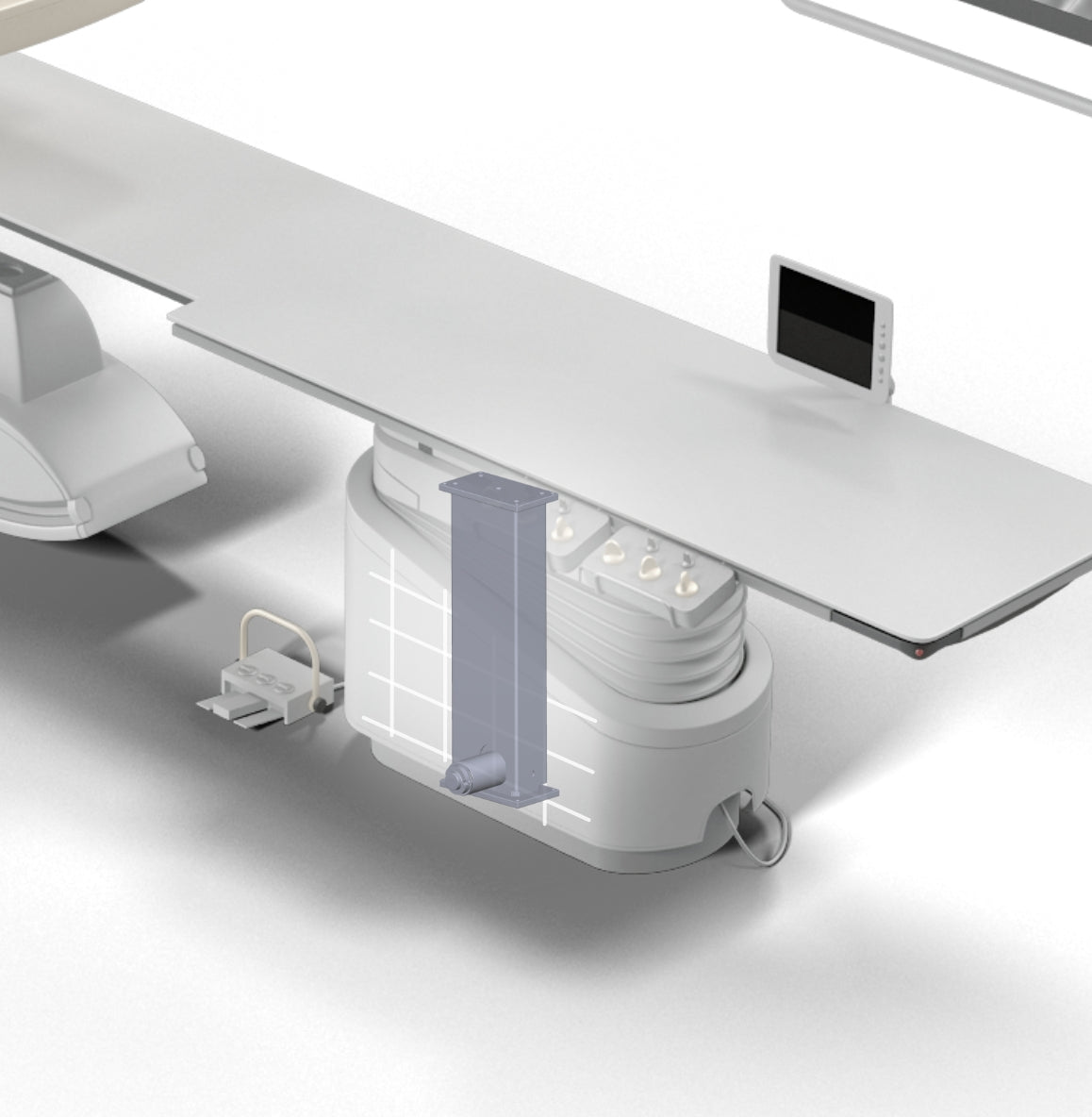

X-Ray Equipment

Height Adjustment

Model

LG-12 Lifting Column

Function

Raises and lowers to control the height adjustment of the X-ray table.

Benefits

Facilitates easy patient transfer onto and off the table, improving accessibility and patient comfort during imaging procedures.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Medical industries.

Key Features

- Versatile Load Capacity

- Hall Effect Feedback Options

- Smooth Reliable Motion

- High Speed

- Maintenance Free

- IP66 Water Protection

Request Custom Specs

Request Custom Specs

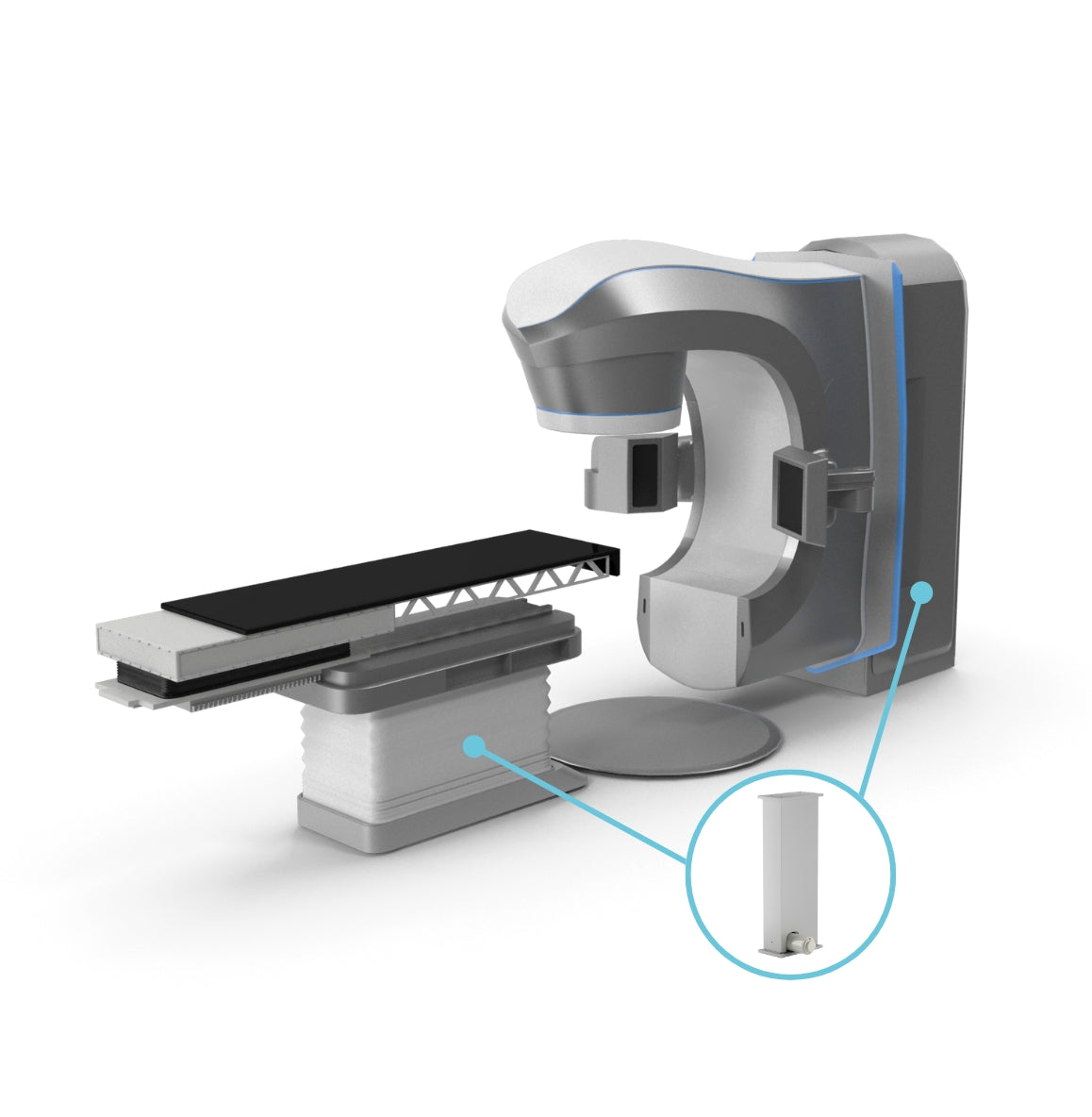

Application

MRI Machines

Linear actuators play a crucial by improving the capabilities and reliability of MRI machines, supporting effective patient diagnosis and treatment in the field of medical imaging.

Challenges

The construction of linear actuators must utilize non-magnetic materials to prevent interference with the MRI’s magnetic field while maintaining structural integrity and performance. Precise positioning of components within the MRI is crucial for accurate imaging; however, magnetic disturbances can affect the actuator's ability to provide accurate and repeatable motion control. Vibrations and noise from actuators can also distort MRI images, reducing diagnostic accuracy and affecting patient comfort. Additionally, the sensitive environments in which MRI machines operate requiring stringent safety, temperature, humidity, and cleanliness standards.

Solutions

Non-magnetic materials like ceramics, titanium alloys, and composites are utilized in the construction of actuators to prevent magnetic interference while ensuring durability and performance. High-resolution feedback systems, are integrated with actuators to achieve precise positioning and compensate for any magnetic disturbances. Noise dampening mechanisms, including vibration isolation mounts, shock absorbers, and sound enclosures, are incorporated to reduce vibrations and noise during MRI operation. Environmental sealing is applied to actuators to protect internal components from temperature fluctuations, humidity, and contaminants, ensuring reliable and long-lasting performance. Certificates such as IEC 61010-1 and IEC 60601-1-2 ensures compliance with international standards for electromagnetic compatibility (EMC) in medical equipment.

Benefits

Effective EMI shielding ensures that actuators operate without interference, maintaining the integrity of MRI imaging protocols. The use of non-magnetic materials in actuator construction eliminates the risk of magnetic disturbances, allowing for precise adjustments within the MRI field. High precision in positioning enhances the accuracy of MRI images, crucial for correct diagnostics. Minimized vibrations and noise improve patient comfort and ensure clearer imaging results. Enhanced environmental protection ensures that actuators remain reliable and effective even in the stringent conditions typical of MRI settings and comply to medical standards.

MRI Machines

Patient Table Height Adjustment

Model

LG-12 Lifting Column

Function

Raises and lowers to control the height adjustment of the patient table.

Benefits

Facilitates easy patient transfer onto and off the table, improving accessibility and patient comfort during imaging procedures.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated

Request Custom Specs

Application

Incubators

Linear actuator ability to perform accurate movements and adjustments within the sensitive environment of an incubator is vital for maintaining optimal conditions for infant care.

Challenges

Size constraints require actuators to be compact enough to fit within limited spaces without sacrificing force or stroke length. Noise and vibration control is crucial as excessive noise and vibrations can disturb the infants. Precision and accuracy in movement control are essential to adjust the position of infants. Durability and reliability are critical to withstand frequent operation and exposure to temperature and humidity fluctuations. Safety compliance with stringent medical device regulations is mandatory. Integration challenges involve ensuring that actuators seamlessly interface with the broader incubator systems and controls for effective operation.

Solutions

To meet these challenges, advanced solutions are implemented, such as compact actuators. Noise-reducing mechanisms such as precision-machined components and dampening materials are utilized. High-resolution feedback systems, such as encoders or sensors, paired with advanced control, ensure precise and accurate movement control. Actuators are designed with high IP rating to protect against environmental factors and ensure longevity. Built-in safety features like overcurrent protection, thermal monitoring, and fault detection mechanisms are included to enhance safety. Collaboration with incubator manufacturers aids in standardizing communication protocols and simplifying integration, supported by comprehensive technical documentation while complying with medical standards such as UL 60601-1.

Benefits

Compact designs allow for efficient use of space without sacrificing performance, essential in the limited confines of incubators. Reduced noise and vibration levels ensure a calm environment conducive to infant development. Precise and accurate control mechanisms adjust infant positioning delicately and maintain optimal environmental conditions. Works in compliance with medical standards to meet stringent quality and regulatory requirements.

Height Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductHeight Adjustment

LG-12 Modular Lifting Columns with Remote Control Selection

See Use Case See ProductIncubator

Height Adjustment

Model

LG-12 Lifting Column

Function

Raises and lowers to control the height adjustment of the incubator.

Benefits

Facilitates easy access for caregivers and medical staff, improving ergonomics and reducing strain during neonatal care procedures.

LG-12 LIFTING COLUMN

The LG-12 is a highly efficient lifting column designed for a wide range of applications, including medical equipment.

Key Features

- High Load Capacity

- Smooth Operation

- Compact Design

- Maintenance Free

- Excellent Price/Performance Ratio

- IP43 Rated