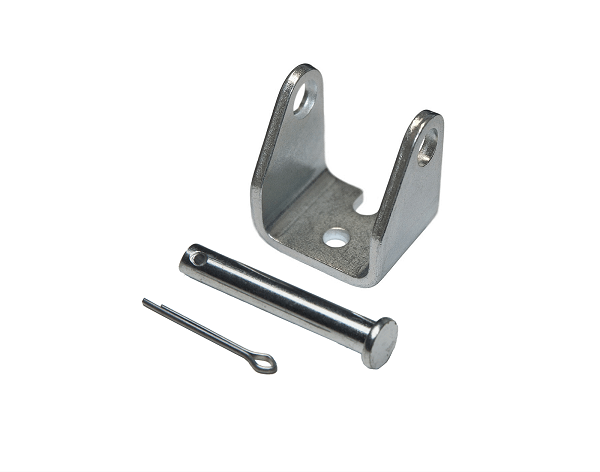

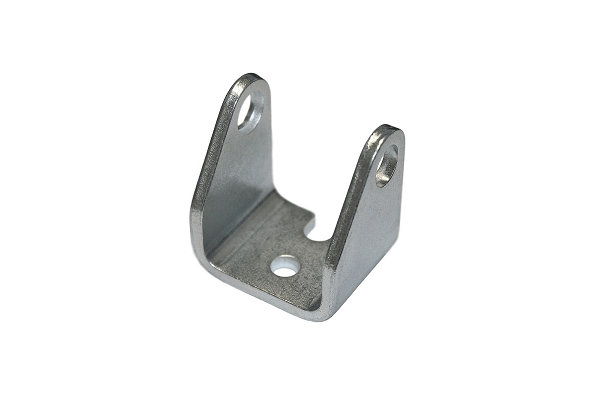

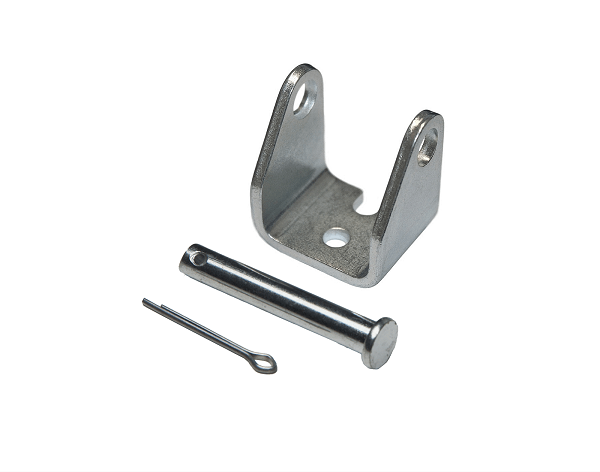

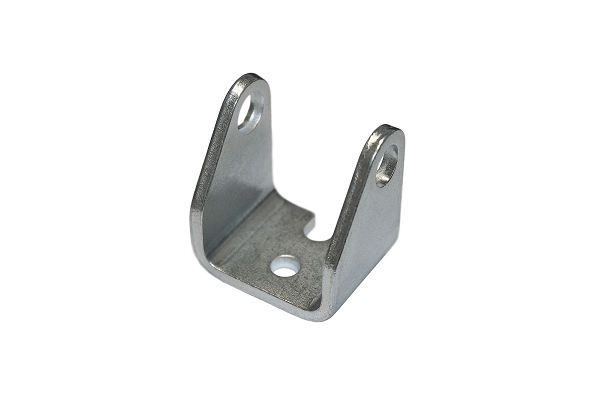

BRK-02-montagebeugels zijn ontworpen om te passen op onze PA-03 (alleen aan de motorkant), PA-04, PA-TS1 en PA-QR1 actuator-modellen. De beugel is ontworpen om meer dan 1,000 lbs aan kracht aan te kunnen en kan vrijwel alles aan. Het lichte, compacte ontwerp voegt een rotatie van 180 graden toe aan uw toepassing zonder de totale lengte noemenswaardig te vergroten. De vermelde prijs is voor één enkele beugel (inclusief de pennen). Elke lineaire actuator heeft twee beugels nodig, één voor elk montagegat.

Elke montagebeugel wordt geleverd met alle benodigde pennen om hem zowel aan de actuator als aan uw toepassing te bevestigen.

Aangepaste opties

Op zoek naar een actuator, maar sluiten de specificaties niet precies aan op uw wensen? We hebben een uitgebreide lijst met maatwerkmogelijkheden zodat u precies krijgt wat u nodig heeft voor uw project. Download het datasheet van dit product en ontdek meer over uw aanpassingsopties!

BRK-02-montagebeugels zijn ontworpen om te passen op onze PA-03 (alleen aan de motorkant), PA-04, PA-TS1 en PA-QR1 actuator-modellen. De beugel is ontworpen om meer dan 1,000 lbs aan kracht aan te kunnen en kan vrijwel alles aan. Het lichte, compacte ontwerp voegt een rotatie van 180 graden toe aan uw toepassing zonder de totale lengte noemenswaardig te vergroten. De vermelde prijs is voor één enkele beugel (inclusief de pennen). Elke lineaire actuator heeft twee beugels nodig, één voor elk montagegat.

Elke montagebeugel wordt geleverd met alle benodigde pennen om hem zowel aan de actuator als aan uw toepassing te bevestigen.

Aangepaste opties

Op zoek naar een actuator, maar sluiten de specificaties niet precies aan op uw wensen? We hebben een uitgebreide lijst met maatwerkmogelijkheden zodat u precies krijgt wat u nodig heeft voor uw project. Download het datasheet van dit product en ontdek meer over uw aanpassingsopties!

Het volgen van een set normen is cruciaal voor bedrijven om ervoor te zorgen dat hun producten en diensten een kwaliteitsniveau halen dat klanttevredenheid bevordert. Bij Progressive Automations gaan we voor niets minder dan het beste voor onze klanten en streven we naar voortdurende verbeteringen. Daarom zijn we verheugd aan te kondigen dat Progressive Automations nu ISO 9001:2015‑gecertificeerd is!

Kwaliteit waarop u kunt vertrouwen – Meer informatie2D/3D-modellen

3D‑modellen

Afhankelijk van uw toepassing zijn er verschillende specificatie-eisen waarmee u rekening moet houden bij het bepalen van de lineaire actuator die u nodig heeft. Deze eisen omvatten kracht, slaglengte, snelheid en montage-afmetingen. Voor gedetailleerde informatie over de actuator kunt u het datasheet of de specificatietabel raadplegen op de productpagina van de geselecteerde actuator. U kunt ook contact met ons opnemen om met een van onze experts te spreken.

Inschakelduur is het deel van de werkperiode waarin een lineaire actuator actief kan blijven. U kunt de inschakelduur van een lineaire actuator berekenen met de volgende vergelijking: Inschakelduur (%) = (Tijd dat de lineaire actuator actief is) / (Tijd voor één werkperiode)

Voorbeeld: Bij een inschakelduur van 25% kan een actuator 5 minuten onafgebroken draaien en moet hij vervolgens 15 minuten rusten voordat hij weer kan functioneren.

Slaglengte is de verplaatsingsafstand van de uitschuivende stang. Om de benodigde slaglengte te bepalen, meet u uw toepassing van de volledig ingetrokken positie tot de volledig uitgeschoven positie. Het verschil is de slaglengte die u nodig heeft.

We raden altijd aan een actuator te kopen met een hogere krachtclassificatie dan uw toepassing vereist. Als u niet zeker bent van de benodigde kracht, kan dit artikel u helpen dit te berekenen: Hoe u de kracht berekent om de juiste lineaire actuator te vinden

Ja, dat is mogelijk. Het hangt echter af van de units die u momenteel gebruikt. Om actuatoren te synchroniseren hebben ze een vorm van terugkoppeling nodig, zoals een potentiometer of hall-effectsensoren. Zie hieronder voor meer informatie in enkele van onze belangrijkste artikelen over het synchroniseren van lineaire actuatoren.

Meerdere lineaire actuatoren tegelijk aansturen

Hoe maakt u gebruik van FLTCON-2 & FLTCON-4 besturingskasten?

De besturingskast die u kiest, moet voldoende spanning en stroom leveren voor uw actuator. Als u niet zeker bent van de specificaties, neem dan contact met ons op.

U kunt ook compatibele besturingskasten vinden op de productpagina van de door u geselecteerde lineaire actuator.

Backdriving treedt op wanneer een actuator onder belasting naar beneden begint te schuiven, hetzij bij overbelasting, hetzij wanneer de actuator is beschadigd. Bekijk de video.

Wat betekenen dynamische en statische belastingswaarden?Dynamische belastingswaarde is het gewicht dat een actuator veilig kan trekken of duwen wanneer hij onder spanning staat. Statische belastingswaarde is het gewicht dat de actuator kan vasthouden of weerstaan zonder backdriving wanneer hij niet onder spanning staat. Stel dat u een actuator op een raam hebt geïnstalleerd en de statische belastingswaarde van de actuator is 100lbs, dan kan er bij harde wind backdriving optreden, wat betekent dat er meer druk op de actuator wordt uitgeoefend, waardoor de 100lbs-belastingswaarde van de actuator wordt overschreden.

Wat is zijdelingse belasting?Zijdelingse belasting is wanneer de actuator krachten ondervindt vanuit het laterale vlak. Actuatoren zijn niet bedoeld om zijdelingse krachten te verwerken; als ze dergelijke krachten ondervinden, zal dit waarschijnlijk de actuator beschadigen of de stang buigen. Het is daarom af te raden om ooit zijdelingse krachten te gebruiken, en zorg er altijd voor dat de actuator volledig in lijn of in sync met uw toepassing staat, zodat hij geen andere belasting opneemt dan de axiale belasting. Bekijk de video.