Verschillende slaglengtes van de modellen zijn op aanvraag beschikbaar. U kunt ons een e-mail sturen naar: sales@progressiveautomations.com

Deze voorbeeldcode gebruikt MegaMoto Plus en een Arduino Uno om de stroom van een lineaire actuator te bewaken; vergelijkbare producten kunnen echter als vervanging worden gebruikt.

/* Code om de stroomafname (in ampère) van de actuator te bewaken en de voeding uit te schakelen als deze

boven een bepaalde waarde komt.

Geschreven door Progressive Automations

19 augustus 2015

Hardware:

- RobotPower MegaMoto-besturingsborden

- Arduino Uno

- 2 drukknoppen

*/

const int EnablePin = 8;

const int PWMPinA = 11;

const int PWMPinB = 3; // pinnen voor Megamoto

const int buttonLeft = 4;

const int buttonRight = 5;//knoppen om de motor te bewegen

const int CPin1 = A5; // motor-terugkoppeling

int leftlatch = LOW;

int rightlatch = LOW;//motorvergrendelingen (gebruikt voor codelogica)

int hitLimits = 0;//begin bij 0

int hitLimitsmax = 10;//waarden om te bepalen of de eindposities zijn bereikt

long lastfeedbacktime = 0; // moet long zijn, anders treedt overflow op

int firstfeedbacktimedelay = 750; //eerste vertraging om de stroompiek te negeren

int feedbacktimedelay = 50; //vertraging tussen terugkoppelingscycli; hoe vaak je de motor wilt controleren

long currentTimefeedback = 0; // moet long zijn, anders treedt overflow op

int debounceTime = 300; //tijd voor het debouncen van knoppen; lagere waarden maken de knoppen gevoeliger

long lastButtonpress = 0; // timer voor debouncen

long currentTimedebounce = 0;

int CRaw = 0; // invoerwaarde voor stroommetingen

int maxAmps = 0; // afschakelgrens

bool dontExtend = false;

bool firstRun = true;

bool fullyRetracted = false;//programmalogica

void setup()

{

Serial.begin(9600);

pinMode(EnablePin, OUTPUT);

pinMode(PWMPinA, OUTPUT);

pinMode(PWMPinB, OUTPUT);//Motoruitgangen instellen

pinMode(buttonLeft, INPUT);

pinMode(buttonRight, INPUT);//knoppen

digitalWrite(buttonLeft, HIGH);

digitalWrite(buttonRight, HIGH);//interne pullups inschakelen

pinMode(CPin1, INPUT);//terugkoppelingsinvoer instellen

currentTimedebounce = millis();

currentTimefeedback = 0;//Initiële tijden instellen

maxAmps = 15;// MAXIMALE STROOM HIER INSTELLEN

}//einde setup

void loop()

{

latchButtons();//knoppen controleren, kijken of we moeten bewegen

moveMotor();//vergrendelingen controleren, motor in- of uitschuiven

}//einde main loop

void latchButtons()

{

if (digitalRead(buttonLeft)==LOW)//links is vooruit

{

currentTimedebounce = millis() - lastButtonpress;// controleer tijd sinds laatste druk

if (currentTimedebounce > debounceTime && dontExtend == false)//als dontExtend is geactiveerd, alle vooruit‑drukken negeren

{

leftlatch = !leftlatch;// als de motor draait, stoppen; als hij stilstaat, starten

firstRun = true;// firstRun‑vlag zetten om stroompiek te negeren

fullyRetracted = false; // zodra je vooruit beweegt, ben je niet volledig ingetrokken

lastButtonpress = millis();//tijd van laatste knopdruk opslaan

return;

}//einde if

}//einde btnLEFT

if (digitalRead(buttonRight)==LOW)//rechts is achteruit

{

currentTimedebounce = millis() - lastButtonpress;// controleer tijd sinds laatste druk

if (currentTimedebounce > debounceTime)

{

rightlatch = !rightlatch;// als de motor draait, stoppen; als hij stilstaat, starten

firstRun = true;// firstRun‑vlag zetten om stroompiek te negeren

lastButtonpress = millis();//tijd van laatste knopdruk opslaan

return; }//einde if

}//einde btnRIGHT

}//einde latchButtons

void moveMotor()

{

if (leftlatch == HIGH) motorForward(255); //snelheid = 0-255

if (leftlatch == LOW) motorStop();

if (rightlatch == HIGH) motorBack(255); //snelheid = 0-255

if (rightlatch == LOW) motorStop();

}//einde moveMotor

void motorForward(int speeed)

{

while (dontExtend == false && leftlatch == HIGH)

{

digitalWrite(EnablePin, HIGH);

analogWrite(PWMPinA, speeed);

analogWrite(PWMPinB, 0);//motor bewegen

if (firstRun == true) delay(firstfeedbacktimedelay); // grotere vertraging om stroompiek te negeren

else delay(feedbacktimedelay); //kleine vertraging om op snelheid te komen

getFeedback();

firstRun = false;

latchButtons();//knoppen opnieuw controleren

}//einde while

}//einde motorForward

void motorBack (int speeed)

{

while (rightlatch == HIGH)

{

digitalWrite(EnablePin, HIGH);

analogWrite(PWMPinA, 0);

analogWrite(PWMPinB, speeed);//motor bewegen

if (firstRun == true) delay(firstfeedbacktimedelay);// grotere vertraging om stroompiek te negeren

else delay(feedbacktimedelay); //kleine vertraging om op snelheid te komen

getFeedback();

firstRun = false;

latchButtons();//knoppen opnieuw controleren

}//einde while

dontExtend = false;//motor weer laten uitschuiven nadat hij is ingetrokken

}//einde motorBack

void motorStop()

{

analogWrite(PWMPinA, 0);

analogWrite(PWMPinB, 0);

digitalWrite(EnablePin, LOW);

firstRun = true;//wanneer de motor gestopt is, firstRun opnieuw inschakelen om opstartstroompieken op te vangen

}//einde stopMotor

void getFeedback()

{

CRaw = analogRead(CPin1); // Stroom uitlezen

if (CRaw == 0 && hitLimits < hitLimitsmax) hitLimits = hitLimits + 1;

else hitLimits = 0; // controleren of de motor de eindposities heeft bereikt en de stroom is gestopt

if (hitLimits == hitLimitsmax && rightlatch == HIGH)

{

rightlatch = LOW; // motor stoppen

fullyRetracted = true;

}//einde if

else if (hitLimits == hitLimitsmax && leftlatch == HIGH)

{

leftlatch = LOW;//motor stoppen

hitLimits = 0;

}//einde if

if (CRaw > maxAmps)

{

dontExtend = true;

leftlatch = LOW; // stoppen als terugkoppeling boven maximum is

}//einde if

lastfeedbacktime = millis();//vorige tijd voor ontvangst van terugkoppeling opslaan

}//einde getFeedback

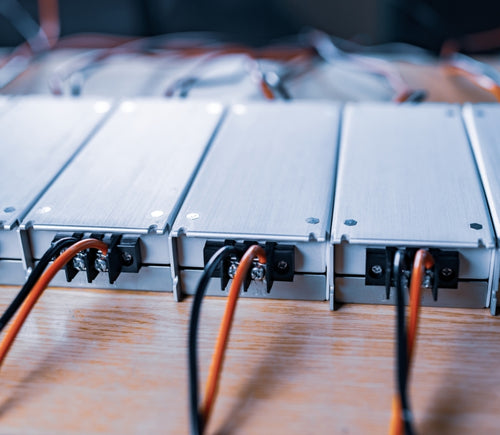

Deze voorbeeldcode laat zien hoe je tot 4 van onze lineaire actuatoren kunt aansturen met de Arduino Uno en LC-82 MultiMoto Arduino Shield; vergelijkbare producten kunnen echter als vervanging worden gebruikt. Deze code is alleen bedoeld voor actuatoren die binnen de stroombeperkingen per kanaal van de MultiMoto vallen, zoals de PA-14 en PA-14P.

/* Voorbeeldcode om tot 4 actuatoren te besturen met de Robot Power MultiMoto-driver.

Hardware:

- Robot Power MultiMoto

- Arduino Uno

Bedrading:

- Verbind actuatoren met de M1-, M2-, M3-, M4-aansluitingen op de MultiMoto-print.

- Verbind de negatieve (zwarte) met de rechteraansluiting, de positieve (rode) met de linker.

- Verbind een 12-volt bron (minimaal 1A per motor onbelast, 8A per motor volledig belast) met de BAT-klemmen. Zorg dat plus en min op de juiste plaatsen zijn aangesloten.

Code aangepast door Progressive Automations op basis van de voorbeeldcode van Robot Power

<a href="http://www.robotpower.com/downloads/" rel="nofollow"> http://www.robotpower.com/downloads/</a>

Robot Power MultiMoto v1.0 demo

Deze software is vrijgegeven in het Public Domain

*/

// neem de SPI-bibliotheek op:

#include <SPI.h>

// L9958 slave-select-pinnen voor SPI

#define SS_M4 14

#define SS_M3 13

#define SS_M2 12

#define SS_M1 11

// L9958 richtingpinnen

#define DIR_M1 2

#define DIR_M2 3

#define DIR_M3 4

#define DIR_M4 7

// L9958 PWM-pinnen

#define PWM_M1 9

#define PWM_M2 10 // Timer1

#define PWM_M3 5

#define PWM_M4 6 // Timer0

// L9958 Enable voor alle 4 motoren

#define ENABLE_MOTORS 8

int pwm1, pwm2, pwm3, pwm4;

boolean dir1, dir2, dir3, dir4;

void setup() {

unsigned int configWord;

// plaats je setup-code hier; wordt één keer uitgevoerd:

pinMode(SS_M1, OUTPUT); digitalWrite(SS_M1, LOW); // HIGH = niet geselecteerd

pinMode(SS_M2, OUTPUT); digitalWrite(SS_M2, LOW);

pinMode(SS_M3, OUTPUT); digitalWrite(SS_M3, LOW);

pinMode(SS_M4, OUTPUT); digitalWrite(SS_M4, LOW);

// L9958 richtingpinnen

pinMode(DIR_M1, OUTPUT);

pinMode(DIR_M2, OUTPUT);

pinMode(DIR_M3, OUTPUT);

pinMode(DIR_M4, OUTPUT);

// L9958 PWM-pinnen

pinMode(PWM_M1, OUTPUT); digitalWrite(PWM_M1, LOW);

pinMode(PWM_M2, OUTPUT); digitalWrite(PWM_M2, LOW); // Timer1

pinMode(PWM_M3, OUTPUT); digitalWrite(PWM_M3, LOW);

pinMode(PWM_M4, OUTPUT); digitalWrite(PWM_M4, LOW); // Timer0

// L9958 Enable voor alle 4 motoren

pinMode(ENABLE_MOTORS, OUTPUT);

digitalWrite(ENABLE_MOTORS, HIGH); // HIGH = uitgeschakeld

/ /******* L9958-chips instellen *********

' L9958 Config-register

' Bit

'0 - RES

'1 - DR - reset

'2 - CL_1 - stroomlimiet

'3 - CL_2 - stroomlimiet

'4 - RES

'5 - RES

'6 - RES

'7 - RES

'8 - VSR - spanningsslewrate (1 schakelt slewl imiet in, 0 schakelt uit)

'9 - ISR - stroomslewrate (1 schakelt slewlimiet in, 0 schakelt uit)

'10 - ISR_DIS - stroomslew uitschakelen

'11 - OL_ON - open-load inschakelen

'12 - RES

'13 - RES

'14 - 0 - altijd nul

'15 - 0 - altijd nul

*/ // instellen op maximale stroomlimiet en ISR-slew-begrenzing uitschakelen

configWord = 0b0000010000001100;

SPI.begin();

SPI.setBitOrder(LSBFIRST);

SPI.setDataMode(SPI_MODE1); // klokpol = laag, fase = hoog

// Motor 1

digitalWrite(SS_M1, LOW);

SPI.transfer(lowByte(configWord));

SPI.transfer(highByte(configWord));

digitalWrite(SS_M1, HIGH);

// Motor 2

digitalWrite(SS_M2, LOW);

SPI.transfer(lowByte(configWord));

SPI.transfer(highByte(configWord));

digitalWrite(SS_M2, HIGH);

// Motor 3

digitalWrite(SS_M3, LOW);

SPI.transfer(lowByte(configWord));

SPI.transfer(highByte(configWord));

digitalWrite(SS_M3, HIGH);

// Motor 4

digitalWrite(SS_M4, LOW);

SPI.transfer(lowByte(configWord));

SPI.transfer(highByte(configWord));

digitalWrite(SS_M4, HIGH);

//Initiële actuatorinstellingen op intrekken bij 0 snelheid zetten (veiligheidsmaatregel)

dir1 = 0; dir2 = 0; dir3 = 0; dir4 = 0; // Richting instellen

pwm1 = 0; pwm2 = 0; pwm3 = 0; pwm4 = 0; // Snelheid instellen (0-255)

digitalWrite(ENABLE_MOTORS, LOW);// LOW = ingeschakeld

} // Einde setup

void loop() {

dir1 = 1;

pwm1 = 255; //richting en snelheid instellen

digitalWrite(DIR_M1, dir1);

analogWrite(PWM_M1, pwm1); // naar pinnen schrijven

dir2 = 0;

pwm2 = 128;

digitalWrite(DIR_M2, dir2);

analogWrite(PWM_M2, pwm2);

dir3 = 1;

pwm3 = 255;

digitalWrite(DIR_M3, dir3);

analogWrite(PWM_M3, pwm3);

dir4 = 0;

pwm4 = 128;

digitalWrite(DIR_M4, dir4);

analogWrite(PWM_M4, pwm4);

delay(5000); // wachten zodra alle vier motoren zijn ingesteld

dir1 = 0;

pwm1 = 128;

digitalWrite(DIR_M1, dir1);

analogWrite(PWM_M1, pwm1);

dir2 = 1;

pwm2 = 255;

digitalWrite(DIR_M2, dir2);

analogWrite(PWM_M2, pwm2);

dir3 = 0;

pwm3 = 128;

digitalWrite(DIR_M3, dir3);

analogWrite(PWM_M3, pwm3);

dir4 = 1;

pwm4 = 255;

digitalWrite(DIR_M4, dir4);

analogWrite(PWM_M4, pwm4);

delay(5000);

}//einde void loop

Deze voorbeeldcode is bedoeld om de enkelkanaals Wasp‑snelheidsregelaar te combineren met de Arduino Uno om de beweging van een lineaire actuator te regelen; vergelijkbare producten kunnen echter als vervanging worden gebruikt.

/*Voorbeeldcode voor de Robot Power Wasp.

Deze ESC wordt bestuurd met RC-signalen met pulsen

van 1000 - 2000 microseconden.

De hoofdlus van dit programma houdt de actuator 1 seconde stil, schuift 2 seconden uit,

stopt 1 seconde, schuift 2 seconden in en herhaalt.

Aangepast door Progressive Automations, op basis van de oorspronkelijke voorbeeldcode "Sweep" uit de

Arduino-voorbeeldbibliotheken.

Hardware:

- 1 Wasp-controller

- Arduino Uno

Bedrading:

Besturingszijde:

- Verbind rood/zwart met +5v en GND

- Verbind de gele draad met je signaalpin op de Arduino (in dit voorbeeld, pin 9)

Vermogenszijde:

- Verbind de +/- van de stroomvoorziening van de motor met de +/- aansluitingen op de Wasp

- Verbind de +/- van de actuator met de overblijvende twee aansluitingen

Deze voorbeeldcode is publiek domein.

*/

#include <servo.h>

Servo myservo; // servo-object maken om een servo aan te sturen

// op de meeste borden kunnen twaalf servo-objecten worden gemaakt

int pos = 0; // variabele om de servo-positie op te slaan

void setup()

{

myservo.attach(9); // koppelt de servo op pin 9 aan het servo-object

}

void loop()

{

myservo.writeMicroseconds(1500); // stopsignaal

delay(1000); //1 seconde

myservo.writeMicroseconds(2000); // signaal volle snelheid vooruit

delay(2000); //2 seconden

myservo.writeMicroseconds(1500); // stopsignaal

delay(1000); // 1 seconde

myservo.writeMicroseconds(1000); // signaal volle snelheid achteruit

delay(2000); //2 seconden

}

Deze voorbeeldcode maakt gebruik van onze relais en Arduino Uno om een lineaire actuator te besturen; vergelijkbare producten kunnen echter als vervanging worden gebruikt. Je kunt ons volledige blogbericht lezen voor meer details.

const int forwards = 7;

const int backwards = 6;//relais-INx-pin koppelen aan Arduino-pin

void setup() {

pinMode(forwards, OUTPUT);//relais als uitgang instellen

pinMode(backwards, OUTPUT);//relais als uitgang instellen

}

void loop() {

digitalWrite(forwards, LOW);

digitalWrite(backwards, HIGH);//Relais in één richting activeren; de niveaus moeten verschillend zijn om de motor te laten bewegen

delay(2000); // 2 seconden wachten

digitalWrite(forwards, HIGH);

digitalWrite(backwards, HIGH);//Beide relais deactiveren om de motor te remmen

delay(2000);// 2 seconden wachten

digitalWrite(forwards, HIGH);

digitalWrite(backwards, LOW);//Relais in de andere richting activeren; de niveaus moeten verschillend zijn om de motor te laten bewegen

delay(2000);// 2 seconden wachten

digitalWrite(forwards, HIGH);

digitalWrite(backwards, HIGH);//Beide relais deactiveren om de motor te remmen

delay(2000);// 2 seconden wachten

}

Deze voorbeeldcode gebruikt onze LC-80, een Arduino Uno, elke lineaire actuator en een stroombron; vergelijkbare producten kunnen echter als vervanging worden gebruikt. Meer details over de code en wat deze doet vind je in onze blogpost.

//Use the jumpers on the board to select which pins will be used

int EnablePin1 = 13;

int PWMPinA1 = 11;

int PWMPinB1 = 3;

int extendtime = 10 * 1000; // 10 seconds, times 1000 to convert to milliseconds

int retracttime = 10 * 1000; // 10 seconds, times 1000 to convert to milliseconds

int timetorun = 300 * 1000; // 300 seconds, times 1000 to convert to milliseconds

int duty;

int elapsedTime;

boolean keepMoving;

void setup() {

Serial.begin(9600);

pinMode(EnablePin1, OUTPUT);//Enable the board

pinMode(PWMPinA1, OUTPUT);

pinMode(PWMPinB1, OUTPUT);//Set motor outputs

elapsedTime = 0; // Set time to 0

keepMoving = true; //The system will move

}//end setup

void loop() {

if (keepMoving)

{

digitalWrite(EnablePin1, HIGH); // enable the motor

pushActuator();

delay(extendtime);

stopActuator();

delay(10);//small delay before retracting

pullActuator();

delay(retracttime);

stopActuator();

elapsedTime = millis();//how long has it been?

if (elapsedTime > timetorun) {//if it's been 300 seconds, stop

Serial.print("Elapsed time is over max run time. Max run time: ");

Serial.println(timetorun);

keepMoving = false;

}

}//end if

}//end main loop

void stopActuator() {

analogWrite(PWMPinA1, 0);

analogWrite(PWMPinB1, 0); // speed 0-255

}

void pushActuator() {

analogWrite(PWMPinA1, 255);

analogWrite(PWMPinB1, 0); // speed 0-255

}

void pullActuator() {

analogWrite(PWMPinA1, 0);

analogWrite(PWMPinB1, 255);//speed 0-255

}

Met dit programma kunt u de slaglengte van een lineaire actuator continu in- en uitschuiven.

SETUP LOOP CODE

void setup() {

Serial.begin(9600); // initialize serial communication at 9600 bits per second

pinMode(out_lim, INPUT_PULLUP); // configures pin 45 as input pin

pinMode(in_lim, INPUT_PULLUP); // configures pin 53 as input pin

pinMode(run_f, OUTPUT); // configures pin 25 as output pin

pinMode(run_r, OUTPUT); // configures pin 30 as output pin

retract(); // retracts the stroke on startup

delay(500);

}

void extend() // this function enables the motor to run

{

digitalWrite(run_f, LOW);

digitalWrite(run_r, HIGH);

}

void retract() // this function reverses the direction of motor

{

digitalWrite(run_f, LOW);

digitalWrite(run_r, LOW);

}

void run_stop() // this function disables the motor

{

digitalWrite(run_f, HIGH);

digitalWrite(run_r, HIGH);

}

void loop() {

int out_lim_state = digitalRead(out_lim); // reads the limit switches and saves its value

int in_lim_state = digitalRead(in_lim);

Serial.print("outer limit switch value "), Serial.println(out_lim_state); // 0 -> limit switch is pressed

Serial.print("inner limit switch value "), Serial.println(in_lim_state); // 1 -> limit switch is not pressed

if (out_lim_state == 0 && in_lim_state == 1) // if outer limit switch is pressed and inner is not (extended all the way)

{

retract(); // retract the stroke

}

else if (out_lim_state == 1 && in_lim_state == 0) // if inner limit switch is pressed and outer is not (reracted all the way)

{

extend(); // extend the stroke

}

else // otherwise do nothing

{

}

delay(5); // delay in between reads for stability

}

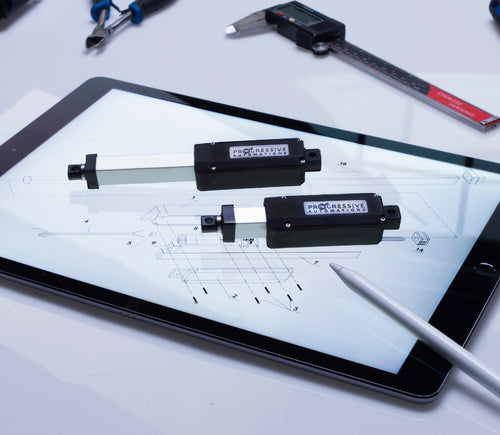

We hebben datasheets, gebruikershandleidingen, 3D‑modellen, bedradingsschema's en meer in onze secties Bronnen en Leercentrum .

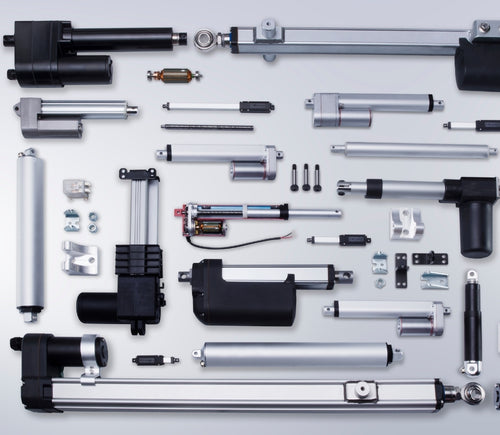

Afhankelijk van uw toepassing zijn er verschillende specificatie-eisen waarmee u rekening moet houden bij het bepalen van de benodigde lineaire actuator. Deze eisen omvatten kracht, Slaglengte, Snelheid en montage-afmetingen. Voor gedetailleerde informatie over de actuator kunt u de datasheet of de specificatietabel raadplegen op de productpagina van de geselecteerde actuator. U kunt ook contact met ons opnemen om met een van onze deskundige engineers te spreken.

Inschakelduur is het deel van de werkperiode waarin een lineaire actuator actief kan blijven. U kunt de inschakelduur van een lineaire actuator berekenen met de volgende vergelijking: Inschakelduur (%) = (Tijd dat de lineaire actuator actief is) / (Tijd voor één werkperiode)

Voorbeeld: bij een inschakelduur van 25% kan een actuator 5 minuten continu draaien en moet hij vervolgens 15 minuten rusten voordat hij weer kan worden bediend.

Ja, onze actuators kunnen voor de meeste toepassingen naadloze vervangingen zijn. Neem contact met ons op als u niet zeker weet voor welke actuator u moet kiezen. U moet de vereiste spanningswaarde, krachtwaardering en Slaglengte weten voordat we een aanbeveling voor een vervangende actuator kunnen doen.

Slaglengte is de verplaatsingsafstand van de uitschuivende stang. Om de vereiste Slaglengte te bepalen, meet u in uw toepassing van de volledig ingetrokken positie tot de volledig uitgeschoven positie. Het verschil is de Slaglengte die u nodig hebt.

We raden altijd aan een actuator te kopen met een hogere krachtwaardering dan wat de toepassing vereist. Als u niet zeker bent van uw krachteisen, kan dit artikel u helpen dit te berekenen: How to Calculate Force to Find the Right Linear Actuator

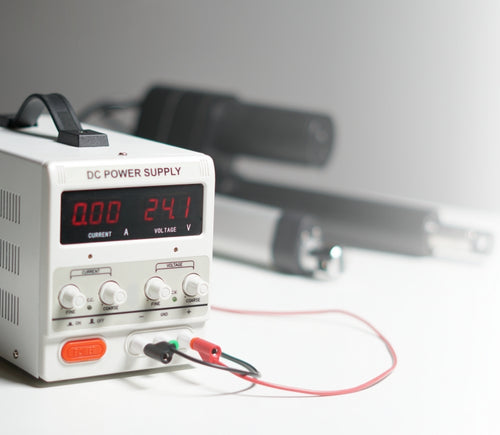

Ja. Het is echter belangrijk dat er voldoende spanning en stroom op uw actuator wordt toegepast. Hier is een artikel dat u verder kan helpen: How to Choose the Right Power Supply for your Linear Actuator

Om synchrone bewegingsbesturing te bereiken, hebt u Terugkoppeling nodig. Wij bieden Terugkoppeling in de vorm van interne Eindschakelaars, potentiometers of Hall‑effectsensoren. Het volgende artikel belicht enkele producten van Progressive Automations die gebruikt kunnen worden voor gesynchroniseerde besturing: Controlling Multiple Linear Actuators at the Same Time

Er zijn meerdere redenen waarom uw lineaire actuator veel geluid kan maken, waaronder overbelasting, zijdelingse belasting of mogelijk binnendringend water. Het kan echter ook zo zijn dat uw actuator simpelweg een actuator met hoge krachtwaardering is en daarom een hoog bedrijfsgeruis heeft. Voor informatie over hoe u dit harde geluid mogelijk kunt verminderen, klikt u hier. Als u vermoedt dat er een probleem is met uw actuator, neem dan contact met ons op.

De meeste van onze lineaire actuators zijn beschikbaar voor maatwerk. Raadpleeg de datasheet van het gewenste product om de volledige mogelijkheden van de maatwerkopties te bekijken. Houd er rekening mee dat er voor de productie een doorlooptijd van ongeveer 20–25 werkdagen geldt, exclusief verzendtijd. Voor elke actuator die wordt aangepast, geldt ook een extra vergoeding. Voor meer informatie over maatwerkbestellingen kunt u contact met ons opnemen via 1800 – 676 – 6123.

Ja, dit is mogelijk. Het hangt echter wel af van de units die u momenteel gebruikt. Om actuators te synchroniseren, is een vorm van Terugkoppeling nodig, zoals een potentiometer of Hall‑effectsensoren. Zie hieronder voor enkele van onze belangrijkste content over synchronisatie van lineaire actuators.

Op dit moment hebben we geen kits beschikbaar. Als u echter een aanbeveling wilt voor de compatibiliteit van bepaalde lineaire actuators met besturingssystemen, stuur ons dan een e‑mail op sales@progressiveautomations.com met de volgende informatie:

• Vereiste spanningswaarde

• Vereiste Slaglengte

• Vereiste krachtwaardering

• Dimensionale beperkingen van uw toepassing

• Beschrijving van uw toepassing waarin de actuator(en) worden geïnstalleerd

Temperatuur kan van invloed zijn op de werking van uw lineaire actuator. Zorg ervoor dat u uw actuator gebruikt binnen de specificaties die in het productinformatieblad worden vermeld. Als u een specifieke vraag heeft over een actuator en temperatuur, neem dan contact met ons op. neem contact met ons op.

Om dit te doen, moet u ervoor zorgen dat de specificaties van uw systeem compatibel zijn met de spannings- en stroomwaardes van de actuator. Als deze specificaties op elkaar aansluiten, is dit mogelijk. Neem contact met ons op als u niet zeker weet voor welke actuator u moet kiezen.

Raadpleeg de datasheet van uw product om deze informatie te vinden. Als uw lineaire actuator op maat is aangepast, stuur ons dan afbeeldingen van het product, inclusief uw ordernummer (indien mogelijk), en mail deze informatie naar sales@progressiveautomations.com

Klik hier voor een lijst met beschikbare 3D‑CAD‑modellen.

De besturingskast die u kiest, moet in staat zijn voldoende spanning en stroom aan uw actuator te leveren. Als u niet zeker bent van de specificaties, neem dan contact met ons op.

U kunt ook compatibele besturingskasten vinden op de productpagina van uw geselecteerde lineaire actuator.

Om dit te doen, moet u ervoor zorgen dat de specificaties van uw systeem compatibel zijn met de spannings- en stroomwaardes van de besturingskast. Als deze specificaties op elkaar aansluiten, is dit mogelijk. Als u niet zeker bent van de compatibiliteit, neem dan contact met ons op.

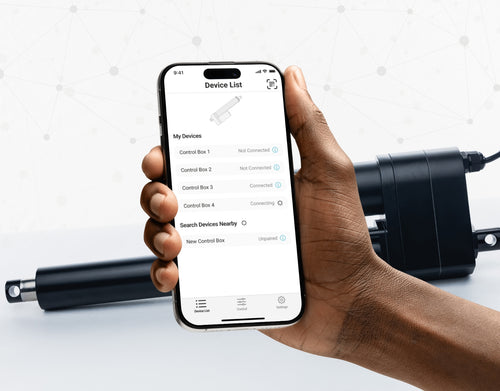

Ja, onze PA-35 kan tot vier lineaire actuators aansturen met een Android-/iOS-apparaat. Voor meer informatie, lees ons uitgebreide artikel over het gebruik van onze Wi‑Fi‑besturingskast en app.

Nee. We hebben echter een grote verscheidenheid aan besturingskasten om uit te kiezen voor elke actuator. Als alternatief kunt u ook tuimelschakelaars gebruiken als een vorm van bewegingsbesturing.

Ja, maar u moet ervoor zorgen dat uw besturingskast voldoende stroom kan leveren en een compatibele spanning biedt. Anders loopt u het risico uw actuator(en) te beschadigen.

Omdat wij primair fabrikanten en distributeurs zijn, hebben we een beperkte hoeveelheid voorbeeldcode beschikbaar. Hoewel we geen specifieke programmering voor uw toepassing kunnen leveren, hebben we wel een groeiende lijst met voorbeeldcodes voor Arduino. Om deze voorbeeldcodes te bekijken, klikt u hier.

We hebben een assortiment AC naar DC voedingen U kunt kiezen uit de producten in onze catalogus. Aangezien de meeste van onze actuatoren werken op 12 VDC, is een 12 VDC autoaccu ook een goede oplossing. Zorg er wel voor dat de aangesloten apparaten voldoende stroom leveren voor uw installatie.

U kunt uw eigen voeding gebruiken als deze voldoende stroom levert en de juiste spanning aan uw systeem. Anders loopt u het risico uw actuator(en) en/of besturingskast(en) te beschadigen.

Ja, de meeste van onze voedingen kunnen worden omgezet tot 230 VAC. Om ons voedselaanbod te bekijken, klikt u hier.

Hoewel het mogelijk is, raden we aan de besturingskast te gebruiken die is inbegrepen bij de hefkolomsets. Deze besturingskasten zijn specifiek geprogrammeerd zodat de hefkolommen in synchrone beweging werken; het gebruik van een controller van een derde partij kan dit compromitteren.

Onze nieuwe LG‑11 biedt echter veel vergelijkbare eigenschappen als de FLT‑11 en kan desgewenst worden gekoppeld aan de FLTCON‑serie besturingskasten en de RT‑11‑afstandsbediening zodat meerdere units in synchrone beweging kunnen lopen. We hebben dual‑hefkolomsystemen beschikbaar zoals FLT-06 of FLT-10 die u een minimale hoogte van 22 inches vanaf de vloer kunnen bieden.

Al onze hefkolommen worden geleverd met besturingskasten en afstandsbedieningen om de units te bedienen. Als u meer wilt weten over de besturingskasten die wij gebruiken, neem dan contact met ons op.

De enige aanpasbare eigenschap van onze tafel-/tv‑liften is de ingangsspanning. Houd er rekening mee dat er een doorlooptijd van 20–25 werkdagen geldt voor de productie van alle maatwerkbestellingen.

Onze gemotoriseerde pop‑up‑tv‑lift kan tv’s tot 60 inch dragen en onze drop‑down‑tv‑liften kunnen tot 95 inch aan. Klik hier om onze tv‑liften te bekijken. Voor nog meer informatie bekijkt u onze gids voor het gebruik van tv‑liften.

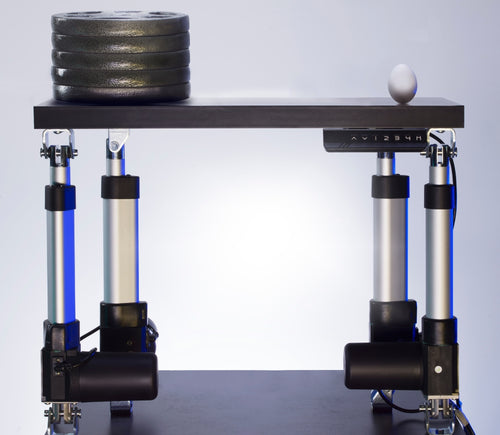

Het draagvermogen van onze tafelliften is afhankelijk van de unit die u kiest. Het minimale draagvermogen in ons assortiment tafelliften is 180 lbs (gelijk aan circa 80 kg) voor onze FLT‑01 Single Table Lift. Het maximale draagvermogen in ons assortiment tafelliften is 330 lbs (gelijk aan circa 150 kg) voor onze FLT‑09 Table Lift Set en FLT‑05 Table Lift Set.

Nee, al onze montagebeugels worden apart verkocht van onze lineaire actuators. We produceren echter compatibele montagebeugels voor elk van onze lineaire actuators. Om te achterhalen welke montagebeugel geschikt is voor uw lineaire actuator, bekijkt u de productpagina van de geselecteerde actuator (waar dit wordt vermeld), of blader door onze catalogus met montagebeugels.

Raadpleeg voor deze informatie onze bedradingsschema's.

Stuur ons alstublieft per e‑mail foto's van uw bedradingsopstelling, zodat we dit verder voor u kunnen onderzoeken. Een van onze sales engineers neemt zo snel mogelijk contact met u op.

E‑mail: sales@progressiveautomations.com

Het kiezen van de juiste elektrische actuator voor uw toepassing is essentieel om deze tot leven te brengen. U moet ervoor zorgen dat hij aan al uw specificaties voldoet en precies kan doen wat u wilt. Daarom hebben we dit handige stroomschema gemaakt voor het selecteren van een lineaire actuator. Het is opgedeeld in vier secties, waarbij elke sectie verschillende opties voor onze actuatoren toont, zodat u duidelijk kunt zien hoe ze van elkaar verschillen:

Backdriving is wanneer een actuator onder belasting naar beneden begint te glijden, wanneer hij ofwel overbelast is of wanneer de actuator is beschadigd. Bekijk de video.

What Does Dynamic and Static Load Ratings Mean?Dynamische belastingswaarde is de hoeveelheid gewicht die een actuator veilig kan trekken of duwen wanneer hij van stroom wordt voorzien. Statische belastingswaarde is de hoeveelheid gewicht die de actuator kan vasthouden of weerstaan zonder backdriving wanneer hij niet van stroom wordt voorzien. Stel bijvoorbeeld dat u een actuator op een raam hebt geïnstalleerd en de statische belastingswaarde van de actuator is 100lbs, dan kan hij bij hevige wind backdriving ervaren, wat betekent dat er meer druk op de actuator wordt uitgeoefend waardoor de 100lbs-belastingswaarde van de actuator wordt overschreden.

What Is Lateral Loading?Laterale belasting is wanneer de actuator krachten vanuit het laterale vlak ondervindt. Actuatoren zijn helemaal niet bedoeld om laterale krachten te verwerken, dus als hij dergelijke krachten ondervindt, zal dit waarschijnlijk de actuator beschadigen of de stang buigen. Daarom wordt geadviseerd om nooit laterale krachten te gebruiken en er altijd voor te zorgen dat de actuator volledig in lijn en gesynchroniseerd is met uw toepassing, zodat hij geen andere belasting opneemt dan de axiale belasting. Bekijk de video.

Bestellingen kunnen op een van de volgende manieren worden geplaatst:

Online: Gebruik ons online bestelproces met opties om te betalen met creditcard of PayPal.

Telefoon: 1-800 – 676 – 6123

E‑mail: sales@progressiveautomations.com

Ja, staffelkortingen worden toegepast als u 7 of meer stuks van hetzelfde product koopt. Overzichten van staffelkortingen vindt u op elke productpagina. Voor meer informatie over onze kortingsstructuur neem contact met ons op.

We accepteren alle gangbare creditcards, PayPal, cheques en overboekingen. Voor klanten die Net Term‑accounts willen opzetten, stuur ons alstublieft een e‑mail om het aanvraagproces te starten.

E‑mail: sales@progressiveautomations.com

Voor prijzen in USD, zorg ervoor dat u ons bezoekt via onze US-site. Voor prijzen in CAD, zorg ervoor dat u ons bezoekt via onze Canadese site.

Alle op de website vermelde producten zijn op voorraad en beschikbaar voor verzending op dezelfde dag als uw bestelling vóór 15:00 uur PST is geplaatst. Als een van onze producten niet beschikbaar is, nemen we zo snel mogelijk contact met u op om te laten weten wanneer de unit weer beschikbaar is.

De verzendkosten van Progressive Automations worden berekend op basis van verschillende factoren, waaronder maar niet beperkt tot: locatie, aantallen en het totale gewicht van uw bestelling. Kleinere artikelen worden per pakket verzonden, terwijl grotere artikelen en bulkbestellingen via een expediteur worden verzonden. We streven er altijd naar om concurrerende verzendprijzen te bieden voor al onze klanten.

Verzendmethoden zijn beschikbaar via online en telefonische bestellingen. Als u een geschatte verzendkost voor uw bestelling wilt ontvangen, kan dit door uw definitieve winkelwagen te bekijken.

We verzenden via meerdere koeriersbedrijven, waaronder FedEx, UPS, DHL en USPS. De door u geselecteerde koerier kan variëren op basis van uw locatie. Grote bestellingen worden verzonden via verschillende expediteurs.

Neem contact met ons op als u vragen hebt over deze opties of als u wilt verzenden met een andere vervoerder/uw eigen verzendaccount.

Klanten in Canada en de VS betalen geen invoerrechten op hun bestellingen. Klanten buiten Noord‑Amerika kunnen onderworpen zijn aan invoerrechten en ‑kosten. Neem contact op met uw lokale overheidsinstantie voor informatie over invoerrechten en belastingen.

Retourneren of ruilen is toegestaan binnen 30 dagen na ontvangst van uw bestelling, zolang het product niet is gebruikt, gewijzigd of beschadigd. Voor meer informatie over ons retourbeleid zie onze sectie Verzending & Retourneren.

Levering naar het continentale deel van de Verenigde Staten kan tussen de 4 en 10 werkdagen duren. Alle andere leveringen kunnen, afhankelijk van uw locatie, ongeveer 10 tot 15 werkdagen duren. Raadpleeg ons verzendbeleid voor meer informatie: Verzending & Retourneren

Helaas biedt Progressive Automations geen gratis verzending aan. U kunt echter wel een korting voor bestelhoeveelheden krijgen vanaf 7 stuks van hetzelfde artikel.

Ja, het L-vormige sta-bureau is flexibel qua oriëntatie en kan naar wens worden geïnstalleerd. Hier is een stapsgewijze handleiding die uitlegt hoe dit mogelijk is: FLT-05 Gebruikershandleiding

OPMERKING: De onderstaande stappen kunnen variëren afhankelijk van het model afstandsbediening dat u heeft. De volgende instructies zijn voor de standaard RT-11-afstandsbediening. Om de maximale hoogte voor uw onderstel in te stellen, ga naar de gewenste hoogte en volg de onderstaande stappen:

- Druk op M; [5 -] verschijnt op het display

- Druk op de UP-knop; [5 -] knippert

- Houd de M-knop ingedrukt totdat u [999] op het display ziet

- De maximale hoogte is nu ingesteld

Om de minimale hoogte voor uw onderstel in te stellen, ga naar de gewenste hoogte en volg de onderstaande stappen:

- Druk op M; [5 -] verschijnt op het display

- Druk op de DOWN-knop; [5 -] knippert

- Houd de M-knop ingedrukt totdat u [000] op het display ziet

- De minimale hoogte is nu ingesteld

Om de limieten te resetten, volgt u de onderstaande stappen:

- Druk op M; [5 -] verschijnt op het display en laat dan los

- Houd M ingedrukt totdat u [555] ziet

- De limieten zijn gereset

OPMERKING: De onderstaande stappen kunnen variëren afhankelijk van het model afstandsbediening dat u heeft. De volgende instructies zijn voor de standaard RT-11-afstandsbediening.

Als u de knoppen van de afstandsbediening ingedrukt moet houden om uw vooraf ingestelde hoogte te bereiken, betekent dit dat uw besturingskast in de momentary-modus staat. Om uw afstandsbediening in de non-momentary-modus te zetten, volgt u de onderstaande stappen

- Zorg ervoor dat er niets onder uw bureau staat, aangezien we de resetprocedure moeten starten

- Houd de DOWN-knop ingedrukt totdat [ASr] op het display verschijnt

- Zodra [ASr] verschijnt, drukt u op [1] en houdt u deze ingedrukt; u kunt twee waarden zien:

a. 10.1 = Non-momentary-modus

b. 10.2 = Momentary-modus

- Voltooi de resetprocedure door de DOWN-knop ingedrukt te houden totdat uw sta-bureau iets zakt en weer omhooggaat.

Onze sta-bureaus hebben 3 instellingen voor botsingsdetectie, die u naar wens kunt instellen. Ga als volgt te werk:

- Zorg ervoor dat er niets onder uw bureau staat, aangezien we de resetprocedure moeten starten

- Houd de DOWN-knop ingedrukt totdat [ASr] op het display verschijnt

- Zodra [ASr] verschijnt, houdt u de UP-[ ^ ]-knop ingedrukt; u kunt drie waarden zien:

a. 10.5 = 11 lbs

b. 10.6 = 22 lbs

c. 10.7 = 33 lbs

- Voltooi de resetprocedure door de DOWN-knop ingedrukt te houden totdat uw sta-bureau iets zakt en weer omhooggaat.

We hebben enkele stappen voor probleemoplossing als u een van de volgende foutcodes ziet op onderstellen met besturingskasten uit de FLTCON-serie:

Controleer de foutcode hier.

Als het probleem na deze stappen aanhoudt, neem dan gerust contact op met onze technische productingenieurs via 1-800-676-6123, of stuur ons een e-mail op sales@progressiveautomations.com.