- Grundlagen

- Wichtige Komponenten und Typen

- Vorteile

- Anwendungen

- Wie man auswählt

- Häufig gestellte Fragen

- Rezensionen

- Abschluss

Electric height adjustable table lifts have revolutionized the way we use and interact with standing desks, production lines, storage, and multiple other uses of adjustable platform systems. The user-friendly controls have made these smart lifting solutions staples in homes, offices, and industries worldwide. This page is dedicated to understanding what electric table lifts are, their uses and benefits, and how you can pick the best option for your requirements.

What Is a Table Lift and How Does It Work?

A table lift is a standard table enhanced with an actuator-powered lifting mechanism. Using electric linear actuators, their purpose is to regulate the height of the table either manually or via remote control. Table lifts can vary in size and shape to accommodate the different needs of their users. This allows for the transformation of the table to fit your work or leisure needs, as well as the adaptation to the varying heights of each user. Besides its primary function of improving work efficiency, an electric height adjustable table lift often comes with smart programmable features. These smart lifting solutions minimize injuries and product damage that may happen in the workplace.

How Does a Table Lift Work?

Electric height adjustable table lifts typically will use motorized lifting columns or standing desks that have actuator-powered lifting mechanisms to do all the mechanical work. One or several actuators can be attached to the table lift base to set all the lifting activity in motion. An electric motor is connected directly to a set of gears and rotates a lead screw to extend and retract telescopic legs. Through our control boxes and compatible remote controls, the height of the frame can be adjusted to meet the user’s needs. Operators simply select a height using the remote control that accompanies the table lift, and it moves accordingly.

Key Components of a Table Lifts and Lifting Columns

Below, we have listed the basic construction of an electric height adjustable table lift and the components that produce the table frame mechanism.

The Platform:

The platform refers to the raised tabletop of the table lift. This aspect of the frame is designed to withstand a variety of environments, making it extremely durable.

The Legs:

Linear actuators are used inside the legs of our motorized lifting columns and standing desks. These electric linear actuators convert electrical power into linear motion for push and pull forces. For our control box to determine what positions the linear actuators have travelled to, there is positional feedback coming from their internal Hall effect sensors. As the motor rotates inside the actuators, square pulses of 5V are generated from the Hall effect sensors as readable signals counted by the control box to determine the travel and positions of each leg.

The Control Box:

Control boxes are essentially the brains of our electric height adjustable tables that allow for programmable smart lifting solutions. They are responsible for reading the positions each leg has travelled to and would then output the necessary amount of power to ensure the legs move to the desired position synchronously. By adjusting how much power is coming from the output, the control box can detect and correct for most disturbances, such as uneven weight distribution, aging motors, and physical obstructions.

Smart Control Options:

Table lift remote controls allow users the ability to provide inputs to the control box of their desk, ultimately moving it up and down. By activation of the remote, signals from the remote are sent to the input ports of the control box. The control box determines how much power needs to be supplied to the output ports for the motorized legs to reach the set point(s), which were commanded by the user holding the remote. Some remotes have buttons that can access preset memory settings, allowing users to save desired heights. Our Bluetooth dongle RT-BT1 connects compatible FLTCON control boxes to your smartphone via the Progressive Motion app, available for both Android and iOS platforms.

The Framing:

All our electric standing desks will come with frames made of steel with a powder-coated finish. This guarantees high structural durability and better stability when in the static position. Steel also holds up well over the years and does not bend or flex when loaded down with weights that are within their weight capacity ratings. While motorized lifting columns don’t come with frames included in a kit, their mounting points with pre-drilled holes allow for integration with custom frames.

Lifting Columns:

Our motorized lifting columns generally have heavier-duty designs, thicker walls, and gear ratios for greater torque than most traditional standing desks. Multiple columns can be paired to the same controller to travel the same speed together synchronously. Their simple and low-maintenance durable designs are ideal for custom cabinetry, home automation, or adjusting industrial workstations and table height. In most cases, they are more commonly found in industrial adjustable platform systems due to the amount of force they are built to withstand, reaching up to 1300 Pfund per leg with our LG-12 Motorized Lifting Column.

View Motorized Lifting Columns

Types of Lifting Mechanisms Explained

Table lifts are conventionally classified according to the type of mechanism applied to perform the raising of the table. Below is a list of the types of table lift mechanisms.

Scissor-lift base:

The power source collapses the base of a pantograph, and the table supports are then extended.

Screw-driven lift:

As the screw rotates, the table moves along its length, creating a simple mechanism.

Rack and pinion table lift:

The rotation of the pinion causes the connected rack to move in a linear motion, lifting the table.

Chain and sprocket:

A vertically oriented chain drive is used to rotate a sprocket thus moving the table upwards.

Articulated:

Alongside the expected vertical movement, this type also offers some horizontal shift. It is attained through the use of linear actuators, which extend jointed arms.

Telescoping:

This method features linear actuators set in the hollow cavity of a larger cylinder.

Manual vs. Electric: What’s Right for You?

While operating a table lift, power is mostly used to raise the height. Lowering it requires much less power and can sometimes be attained using a slow-release mechanism. All table lifts can be broadly divided into manual and automatic, depending on the type of power source utilized in them.

Manual Table Lifts

For a hand-operated lifting table, the operator uses mechanical devices and tools such as a crank, ratchet, screw, or pump to initiate the lift mechanism. One can either turn this with a hand or pedal with one’s foot. These two propelling methods work well for comparatively small tables, where the table lifts do not have to support heavyweights. Since manual table lifts do not require electricity, users have the portability to take them anywhere for as long as they need without having to recharge batteries. Pneumatic-assisted manual alternatives are also suitable for users who are willing to apply some manual force to change height positions, prefer smaller-sized workstations, and can work with a lower weight capacity.

Electric Table Lifts

Most home and office settings will find electric height adjustable table lifts as solid all-rounders, offering smart lifting solutions and advanced safety features. They work well for users who enjoy smart programmable table frames, require moderate weight capacity, and prefer the convenience of electric motors that do all the physical work when changing height positions. Users who are elderly, injured, or physically limited will find the convenience of automatic electric motors especially useful. Certain models also have configurable options that can work with portable rechargeable batteries for greater portability and operation without access to wall outlets. The advanced technology behind electric standing desks and motorized lifting columns also allows for configurations with three or even four legs that move synchronously if users require more weight capacity, greater stability, or a larger surface area.

Progressive Motion App: Wireless Smartphone Table Lift Controls

Top Benefits of Using an Adjustable Table Lift

Automating equipment is advantageous for all, especially when it comes to lifting and positioning heavy loads and improving work environments. Thanks to technological advancements, the use of table lifts has become more widespread. These adjustable platform systems are predominantly utilized to minimize accidents, provide further convenience, and enhance productivity. A few key advantages are listed below.

Ergonomic Height Adjustment

An adjustable table frame can be placed on nearly any surface, with the most conventional position for the table lift being directly on the floor. Through the versatility of telescopic legs, our frames and motorized lifting columns can reach quite significant extended heights and compact retracted heights to meet the needs of all users.

Smooth and Reliable Motion

The table can reach any height within its range smoothly via the remote control. Movement is seamless and produces low noise. Furthermore, it can maintain this height even if a power failure occurs.

Modular Versatility

The platform can be equipped with a wide range of additional fixtures. This can be anything from regular barriers and gates to unconventional tilt-tops, turn-tables, or conveyors. If used for highly specialized purposes, the platforms can feature tops provided with clamps or other special work components.

Portable Operation

Many two-legged configurations of standing desks and motorized lifting columns are able to operate with 24 V DC portable batteries when paired using the FLTCON-2-24VDC control box. These configurations, combined with matching caster wheels, are essentially portable and semi-portable lifting tables that allow you to transport your table lift and belongings with ease.

Programmable Features

When paired with advanced remote controls, the desired height positions of the table can be programmed and incorporated into preset memory settings. Control boxes are also programmed with safety features that include overheat/duty cycle protection, child lock/safety lock features, maximum and minimum height limits, soft start and stop, and collision detection.

Low Maintenance & Long Life

Being reliable, durable, and sturdy in nature, standing desks and motorized lifting columns are designed to withstand considerable loads over long years of heavy-duty service and require minimal maintenance. This is backed by our 96-month (8-year) warranty for standing desk frames and 84-month (7-year) warranty for motorized lifting columns.

Improved Working Conditions & Productivity

Table lifts help productivity & posture improvement for workers who rely on their physical activity when working, reducing overall fatigue and risk of injuries. If certain lifting is repetitive and continuous, injuries are. From back pain and carpal tunnel syndrome to pinched fingers or even fractured bones, ergonomic lifts eliminate these issues and risks.

Applications of Electric Table Lifts in Daily Life

Table lifts can be used for various purposes in homes and offices, and in industrial workstations. Let’s take a look at the most common ones.

Standing Desks

The most popular use of a table lift is as the foundation of a standing desk. The ability to adjust the height of a table is the key feature, allowing the user a selection of desired table heights. Due to the specific construction of the electric table lift mechanism, it is simple to organize computer wires and other peripherals through added cable management accessories that are easily integrated with the standing desk.

Due to the specific construction of the electric table lift mechanism, it is simple to organize computer wires and other peripherals through added cable management accessories that are easily integrated with the standing desk.

Coffee Tables

It may seem that any compact surface can serve as a coffee table. Nonetheless, a small table with a lifting top definitely adds a bit of a futuristic note to your interior. As such, your enhanced coffee table will make a great piece of minimalistic or hi-tech furniture.

Kitchen Stations

Continuing on the topic of domestic convenience, table lifts can also be used to enhance a kitchen table or worktop. Small kitchens are an issue in many living spaces, and thanks to the frame’s adjustability in width and height, it is an effective solution to adjust to spatial restrictions.

Manufacturing & Storage Spaces

The technical specifications of models intended for such industrial purposes differ from models and specifications used for domestic purposes. It starts visually. Factories typically require larger, sturdier tables to cater to the significant weight requirements. On top of that, industrial table lifts should feature durable metallic tabletops as well as more complex lifting mechanisms. In such table lift models, security functions are more advanced than in other models. Specific applications in manufacturing and storage spaces include loading and unloading, conveyor belt systems, pallet handling, etc.

Choosing the Right Lifting Columns for Your Project

Selecting the right motorized lifting columns is one of the most important steps in designing a functional and reliable lifting table or adjustable platform system. Understanding how to balance lifting capacity and stroke length while matching your frame size compatibility will help you choose the most suitable columns for your project.

1. Understanding Lifting Capacity

The lifting capacity of a column determines the maximum load it can raise safely and consistently. Each column is rated for both dynamic (moving) and static (stationary) loads. It’s important to calculate not just the weight of the tabletop or structure but also any additional equipment, such as monitors, tools, or machinery, that will rest on it.

For most office or home setups, columns rated for 180 Pfund per leg or higher are usually sufficient. For heavier-duty applications like industrial workstations or laboratory tables, consider models rated for 230 Pfund per leg or higher and multiple columns in sync. Exceeding a column’s load limit can result in reduced speed, uneven lifting, or long-term motor wear, so it’s best to choose a system that provides a safety margin above your expected weight requirements.

2. Stroke Length and Height Range

Stroke length defines how far the motorized lifting columns can extend and retract, directly affecting the total height range of your system. For example, a column with a 25” stroke may allow a desk to move from sitting to standing height, while industrial lifting tables might require longer strokes to accommodate specialized machinery or assembly equipment.

When choosing stroke length, consider both ergonomics and available space. For a desk lift for DIY setups, ensure the height range suits your standing and seated comfort requirements. For multi-stage telescopic legs, compact retracted sizes allow for a smaller frame footprint while maintaining a long extension range, ideal for tight spaces or compact designs.

3. Frame Size Compatibility

Your frame size compatibility determines how well the motorized lifting columns integrate with the base structure. A mismatch in dimensions can cause instability, uneven lifting, or unnecessary stress on the system. If you’re building from scratch, start by defining your tabletop or load surface dimensions, then select columns that provide sufficient spacing for balance and load distribution. Our motorized lifting columns have mounting points with pre-drilled holes for ease of integration, designed to integrate with a wide range of custom frames.

4. Controls and Customization

Beyond the mechanical specifications, consider your control system—whether you prefer simple up/down functionality, synchronized multi-leg motion, or safety and programmable features like preset memory settings. Many modern columns include Hall effect sensors that can output positional feedback for precise synchronization and positioning.

Synchronized Systems: Achieve True Synchronization

Häufig gestellte Fragen

- Wir bieten eine breite Palette an Hubsäulen und Tischliften mit Tragfähigkeiten von 30 kg bis 590 kg pro Bein. Mit vier synchronisierten LG-12 Modul-Hubsäulen erreichen wir sogar bis zu 2360 kg. Kann ich das Tischliftsystem selbst montieren oder benötige ich einen Fachmann?

- Ja – unsere Liftsysteme sind für die einfache Selbstmontage konzipiert und werden mit Bedienungsanleitungen und Hinweisen zur Fehlerbehebung geliefert. Sind Ihre Tischlifte mit individuellen Tischplatten kompatibel?

- Ja, individuelle Tischplatten sind innerhalb des Verstellbereichs unserer Tischliftrahmen möglich. Die Maßzeichnungen finden Sie in unseren Benutzerhandbüchern. Wie steuere ich die Höhenverstellung eines Hubtisches?

- Unsere Hubtische und Hubsäulen werden als Set mit einer kabelgebundenen Fernbedienung mit Auf- und Ab-Tasten zur Höhenverstellung geliefert. Alternativ können Sie drahtlose Funkfernbedienungen oder Bluetooth-Dongles verwenden, um kompatible FLTCON-Steuergeräte über die Progressive Motion App mit Ihrem Smartphone zu verbinden. Die App ist für Android und iOS verfügbar. Können Ihre Hubtische Voreinstellungen für bevorzugte Höhen speichern?

- Ja, viele unserer kabelgebundenen Fernbedienungen, wie z. B. die RT-11, ermöglichen es unseren Hubtischen und motorisierten Hubsäulen, bis zu 4 programmierbare Tischhöhen zu speichern. Was ist der Unterschied zwischen einer Hubsäule und einem Hubtischgestell?

- Einzelne Hubsäulen bestehen aus einem teleskopierbaren Bein (oder einer modularen Säule), das aus- und eingefahren werden kann. Ein oder mehrere motorisierte Hubsäulen können zu einem Hebesystem kombiniert werden. Diese werden als Säulensets mit der benötigten Steuereinheit und Fernbedienung verkauft. Unser Tischgestell besteht aus einem kompletten Rahmen (oft mit 2 oder 3 Beinen), der zu einer Konstruktion zusammengebaut wird, auf der Sie Ihre Tischplatte montieren. Zum Lieferumfang gehören Querträger, Montagehalterungen, Kabelbäume, Fernbedienungen usw. Können Tischlifte im Freien oder in industriellen Umgebungen eingesetzt werden?

- Sie können in industriellen Tischliften oder in kontrollierten Innenräumen für Anwendungen eingesetzt werden, die innerhalb der zulässigen Tragfähigkeit liegen; Wir bieten jedoch keine Tischlifte für den Außenbereich an, die witterungsbeständig sind. Welche Stromversorgung wird für elektrische Tischlifte benötigt?

- Die meisten unserer Tischlifte und Hubsäulen werden mit 110 V Wechselstrom an einem FLTCON-kompatiblen Steuergerät betrieben, das als Stromversorgung für den elektrischen Tisch dient. Welche Sicherheitsmerkmale bieten Ihre Hubtische und Hubsäulen?

- Zu den Sicherheitsmerkmalen unserer Tischlifte gehören Überhitzungsschutz, Kindersicherung, maximale und minimale Höhenbegrenzung, Sanftanlauf und -stopp sowie Kollisionserkennung. Wie wähle ich das richtige Hubtischsystem für meine Anwendung aus?

- Achten Sie bei der Auswahl der Komponenten Ihres Tischliftsystems auf folgende Spezifikationen:

• Geschätzte Tragfähigkeit, die Sie benötigen.

• Anzahl der benötigten Beine.

• Benötigter Höhenbereich für Ihren Anwendungsfall. • Benutzerpräferenzen für voreingestellte Speichereinstellungen, drahtlose/kabelgebundene Steuerung und/oder App-Integration.

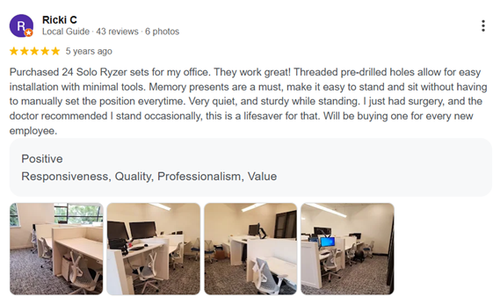

Rezensionen

Abschluss

Wir hoffen, Sie fanden diesen Artikel genauso informativ und interessant wie wir, insbesondere wenn Sie nach einer Anleitung zur Auswahl geeigneter Schreibtischgestelle und motorisierter Hubsäulen für Ihre Anwendung gesucht haben. Sollten Sie Fragen zu unseren Produkten haben oder Schwierigkeiten bei der Auswahl der passenden Modelle für Ihre Bedürfnisse haben, kontaktieren Sie uns gerne! Wir sind Experten auf unserem Gebiet und helfen Ihnen gerne bei allen Fragen weiter!sales@progressiveautomations.com | 1-800-676-6123