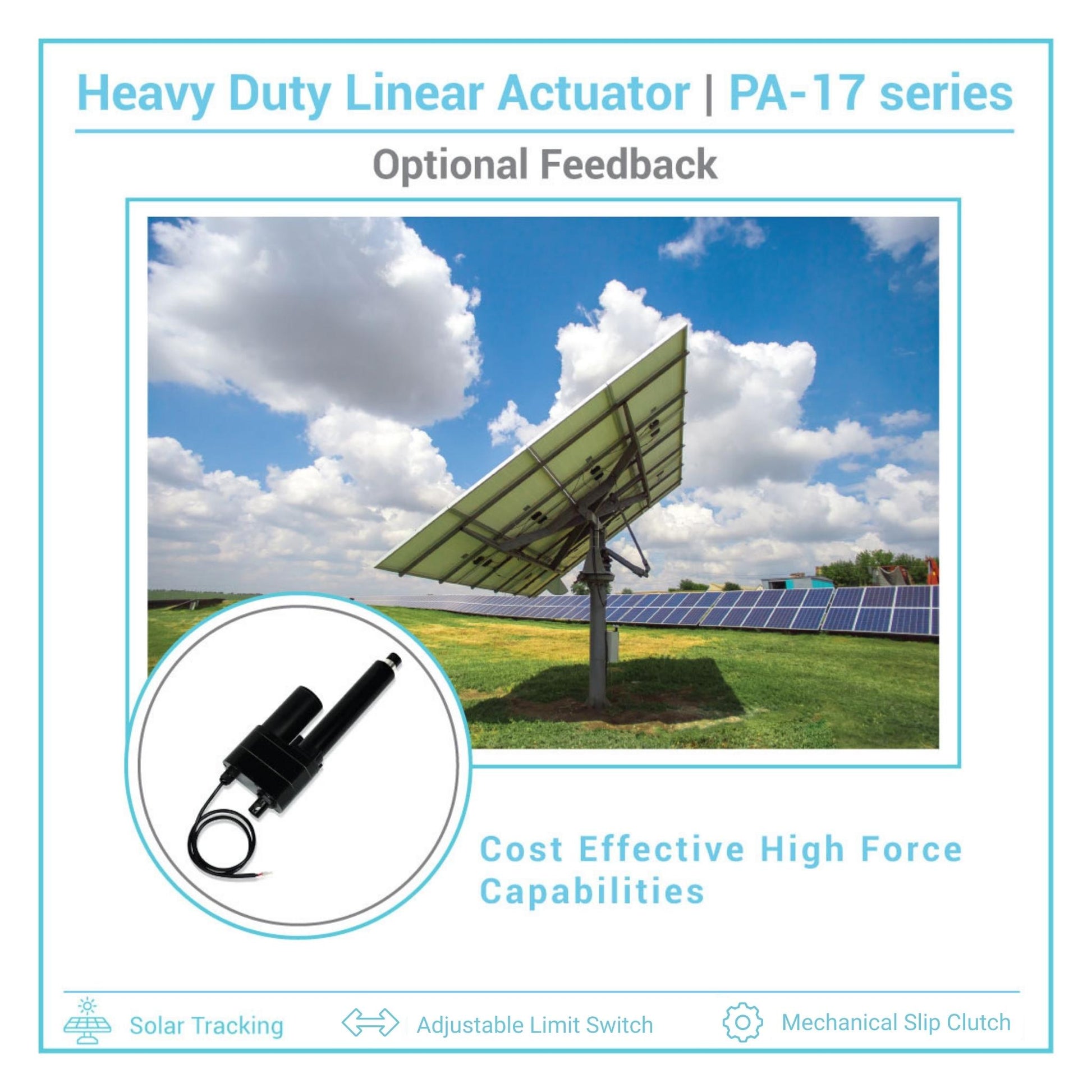

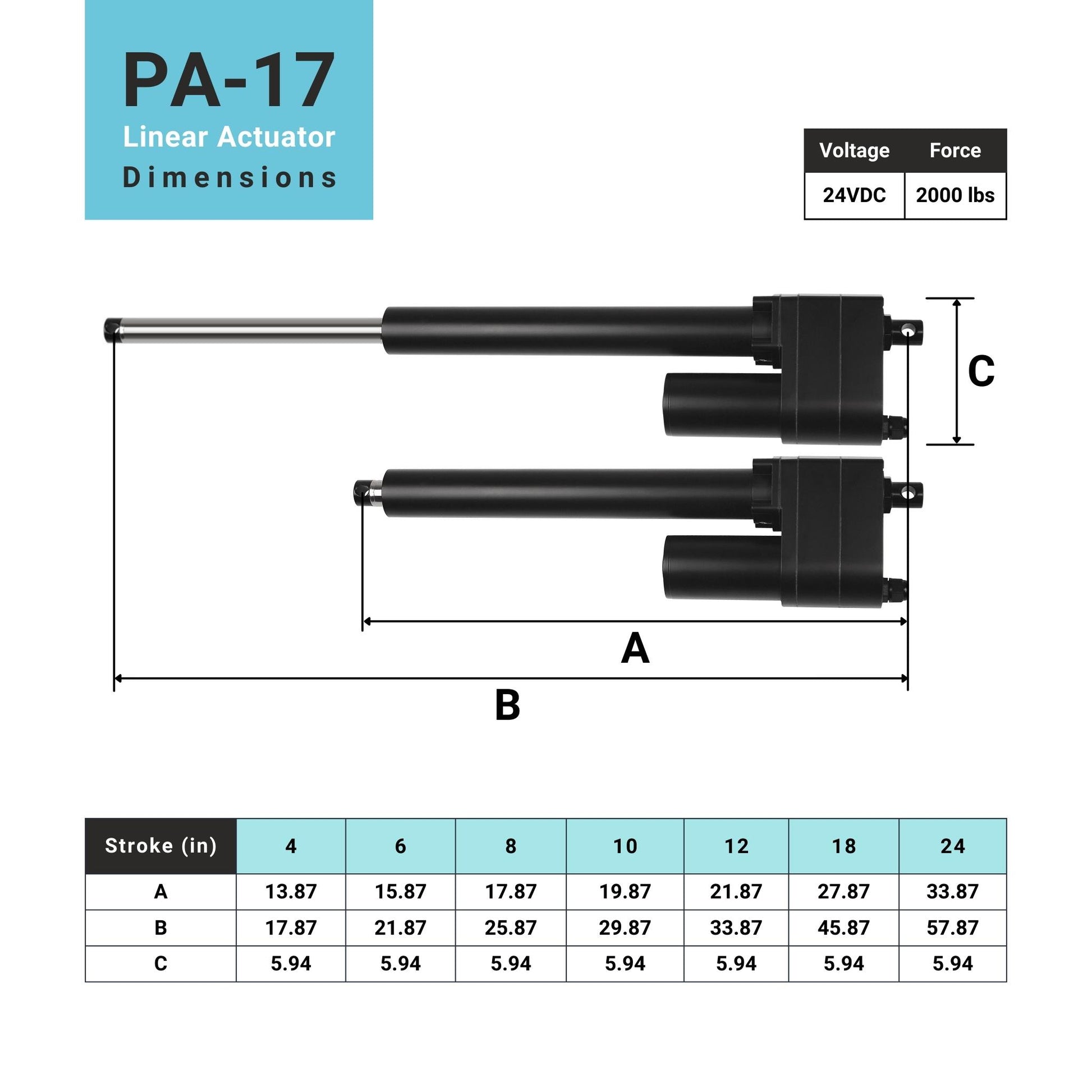

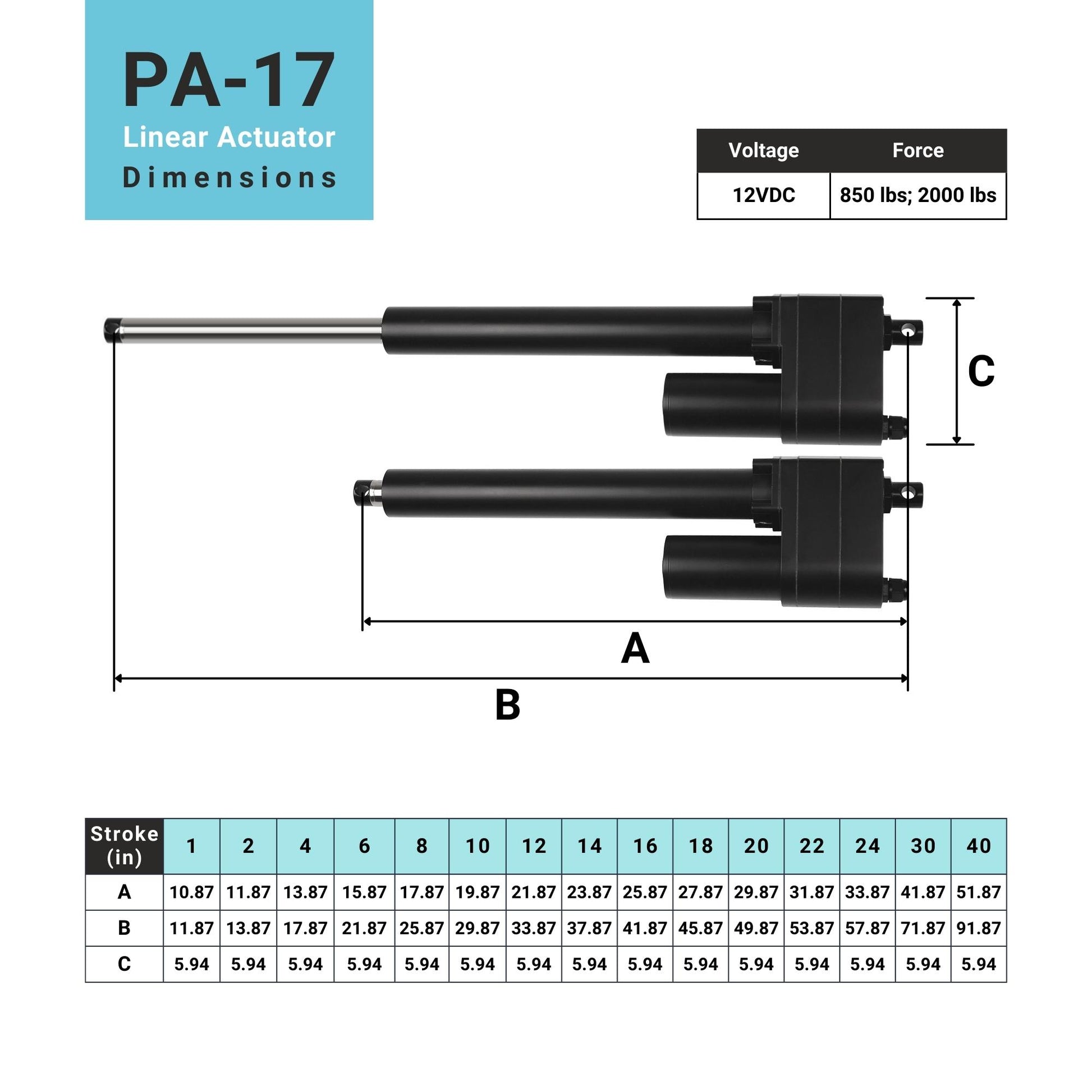

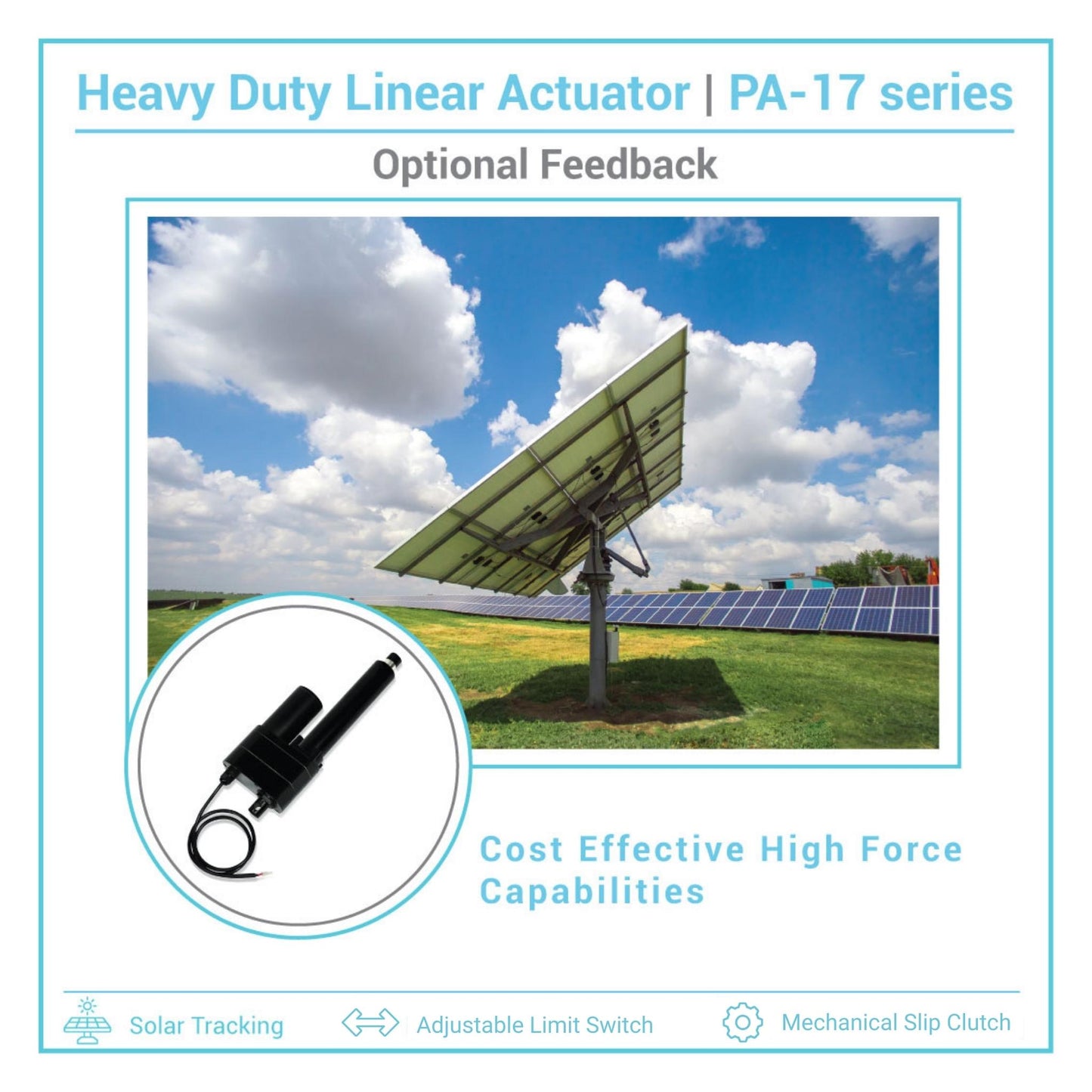

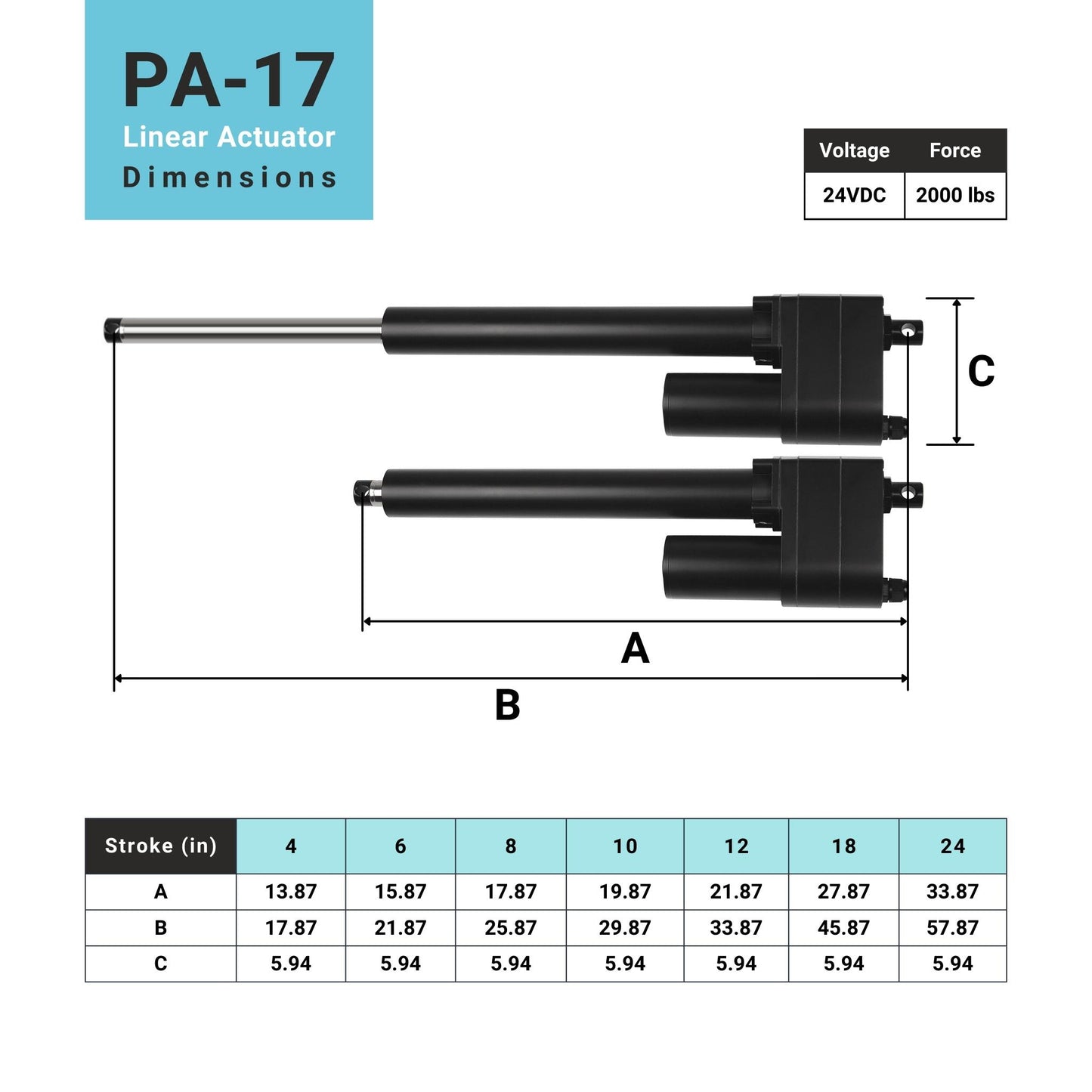

The PA-17 Heavy Duty Linear Actuator provides cost-effective high force capabilities. The stainless steel shaft accompanied by metal gears allows it to push and pull up to 2000 lbs, and hold up to 4000 lbs. The environmental protection rating provides a versatile unit able to withstand dust, water, and harsh environments. The heavy-duty actuator is the only unit in our line of products with adjustable limit switches. This feature allows the user full control over where to start and stop the actuator. We also have this model available with potentiometer feedback here!

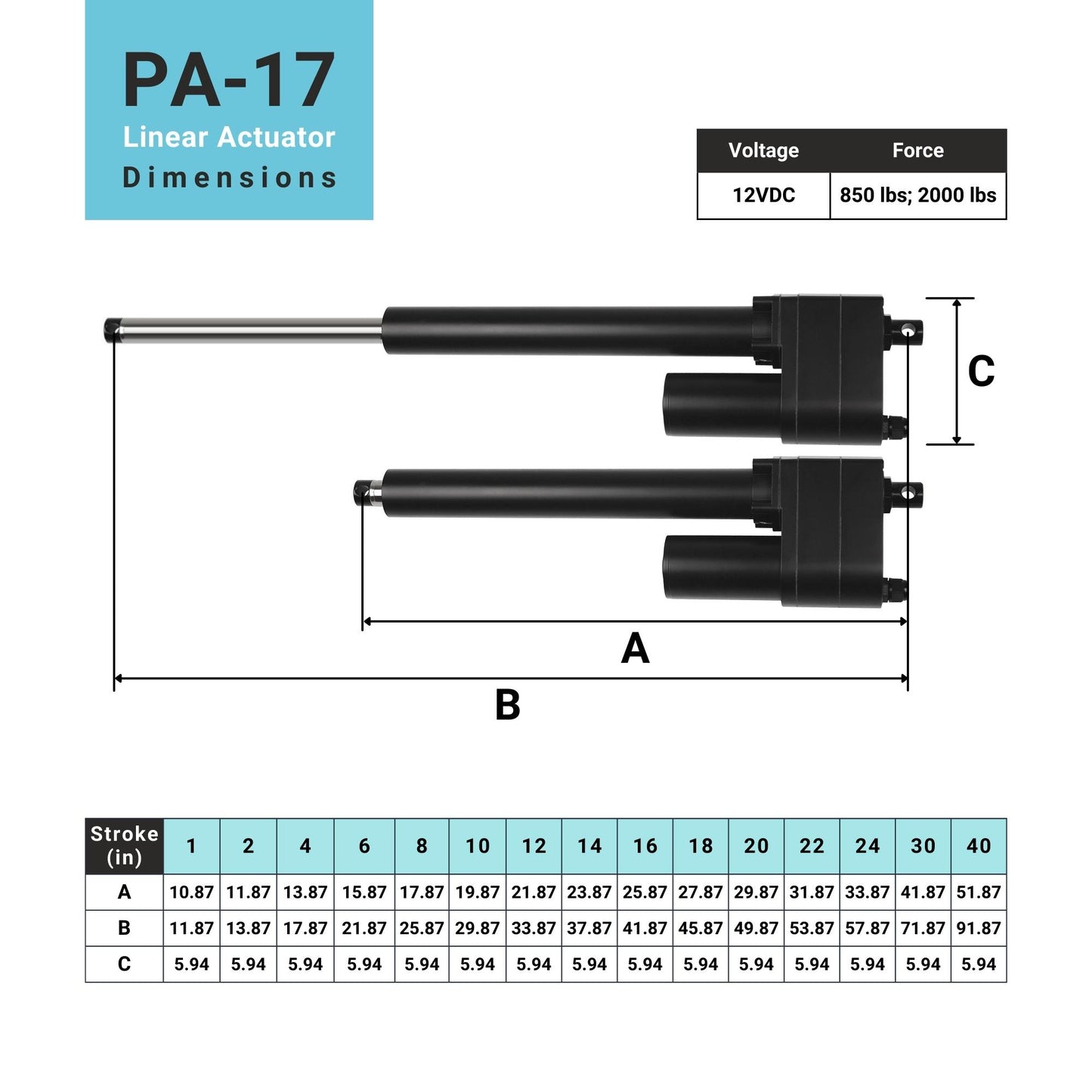

This unit can be found in industries such as manufacturing, renewable energy, agriculture, and industrial automation. For a full list of specifications, customization options, and dimensional drawings, please see our PA-17 Data Sheet.

Note: limit switches are not included in stroke lengths longer than 24".

Actuators Comparison ChartMOUNTING OPTIONS:

The BRK-17 bracket, designed for the Heavy Duty Linear Actuator, allows for a simple installation process. For more detailed information and specifications, please see our brackets product page.

CONTROL SYSTEMS:

Custom options

Looking for an actuator but the specifications don't exactly match what you require? We have an extensive list of customization capabilities to ensure you get exactly what you need for your project. Download this product's data sheet and find out more about your customization options!

The PA-17 Heavy Duty Linear Actuator provides cost-effective high force capabilities. The stainless steel shaft accompanied by metal gears allows it to push and pull up to 2000 lbs, and hold up to 4000 lbs. The environmental protection rating provides a versatile unit able to withstand dust, water, and harsh environments. The heavy-duty actuator is the only unit in our line of products with adjustable limit switches. This feature allows the user full control over where to start and stop the actuator. We also have this model available with potentiometer feedback here!

This unit can be found in industries such as manufacturing, renewable energy, agriculture, and industrial automation. For a full list of specifications, customization options, and dimensional drawings, please see our PA-17 Data Sheet.

Note: limit switches are not included in stroke lengths longer than 24".

Actuators Comparison ChartMOUNTING OPTIONS:

The BRK-17 bracket, designed for the Heavy Duty Linear Actuator, allows for a simple installation process. For more detailed information and specifications, please see our brackets product page.

CONTROL SYSTEMS:

Custom options

Looking for an actuator but the specifications don't exactly match what you require? We have an extensive list of customization capabilities to ensure you get exactly what you need for your project. Download this product's data sheet and find out more about your customization options!

Following a set of standards is crucial for businesses to ensure their products and services can meet a level of quality that promotes customer satisfaction. At Progressive Automations, we aim for nothing but the best for our customers and strive toward continual improvements. Because of this, we are excited to announce that Progressive Automations is now ISO 9001:2015 certified!

Quality Assured