One of the most important steps in selecting a linear actuator is choosing the appropriate force rating. It is quite simple when the application requires a load to be lifted vertically, wherein the weight of the load being lifted is equal to the force required from the actuator. A more challenging scenario is if you have a hinge-type application, as commonly seen with lids, trapdoors, and windows.

In this article, I will use a sample trapdoor application to show basic force concepts. The goal is to visually highlight the effects of the actuator mounting position to the actual force required from the actuator. This will then allow you to mount your actuator in the most efficient way or encourage you to choose a higher force actuator for less efficient mounting positions.

Weight of the Trapdoor

For our sample trapdoor application, the load will be the door itself. Assuming the door is a symmetrical object, the center of gravity will be exactly in its center. That is where the force of gravity will be located. This is the force that must be overcome to move the door open.

The Angle of Force of Gravity

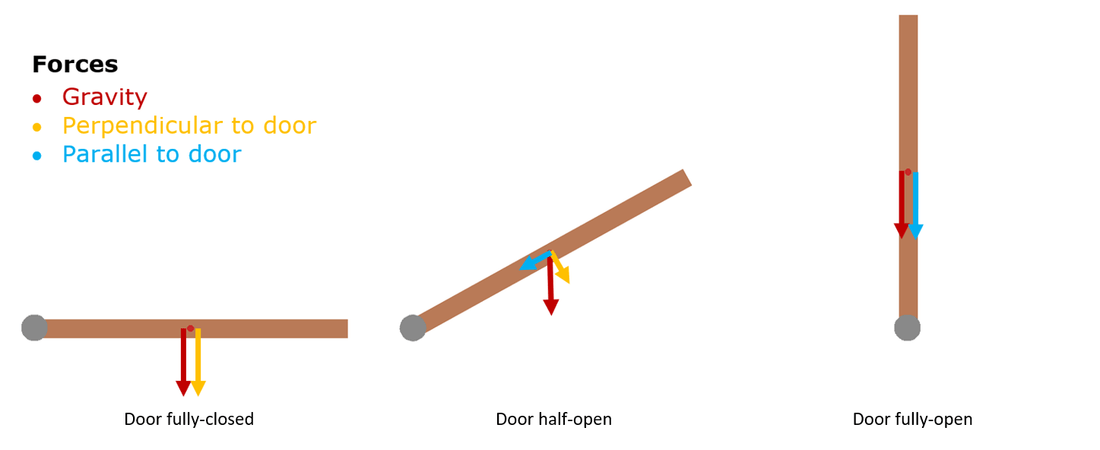

Imagine that you are underneath the door and need to push it open. You will find that it will require the most force when it is fully closed. As it opens, the force required will gradually reduce until it’s fully-open and you hardly need any force to keep it up.

This is because the force of gravity on the door is broken down into 2 components as seen in the diagram below. Note that the size of the arrows represents the force required relative to the other forces.

In this scenario, the force your hand is applying only needs to match the force that is perpendicular to the door as shown with the yellow arrows. This force is initially equal to the force of gravity when the door is fully closed and then reduces to zero when the door is fully open. This is the same when you install a linear actuator. Meaning the greatest force required for this application will be when it is fully closed.

Location of Force on the Trapdoor

In the diagram above, the yellow arrows are the forces required to move the door if the door is pushed from that point. For this application, the door acts as a lever. This means if you apply force farther from the hinge compared to the Force of Gravity, then you will require less force.

The Angle of Actuator Force

Earlier we had discussed how the force required to open the door will vary depending on the angle of the door. The same concept applies to the angle of the actuator. The force that the actuator exerts will be divided into 2 components as seen in the diagram above.

The force perpendicular to the actuator (yellow) is the only component that moves the door. When the actuator is parallel to the door, the door will not open despite exerting a tremendous amount of force. On the other hand, when the actuator is perpendicular to the door it will be able to use 100% of the force exerted to open it. Essentially all forces that are parallel to the door are wasted.

In conclusion, the most efficient mounting position for the actuator will be connected to the very end of the door (maximizes the leverage) and perpendicular to the door (maximizes actuator force applied to the door).

Something to consider is the length of the actuator that will be required to open the door to the desired height. If the actuator was mounted closer to the hinge (requires more force), then a much shorter movement will be required. In this case, it is a game of compromises between efficiency in force, and efficiency in space.

I hope that you found this article helpful in your journey to selecting the most ideal linear actuator for your application. We encourage you to give us a call and speak to our many helpful engineers at 1-800-676-6123.